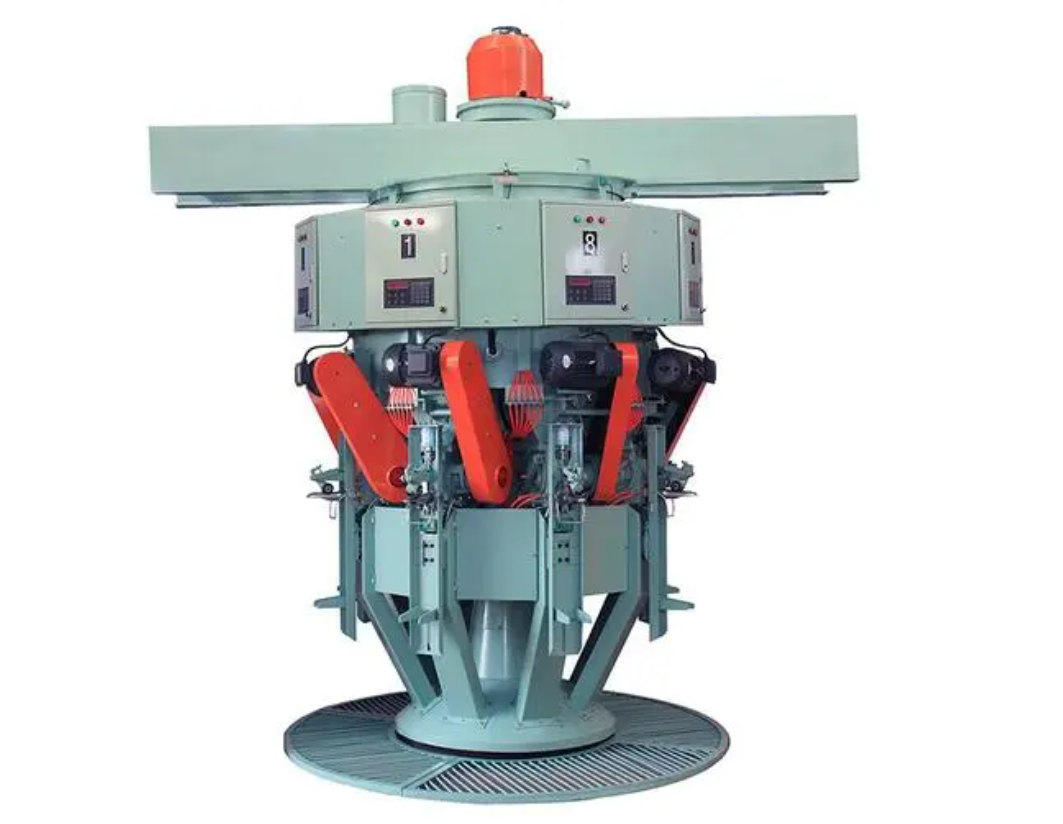

50 Kg Automatic Rotary Cement Sand Bag Bag Machine

Incazelo yomkhiqizo

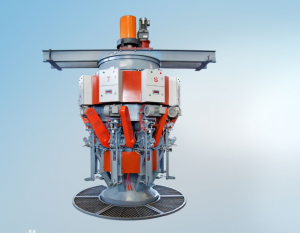

Umshini wokupakisha usimende ojikelezayo we-DCS uwuhlobo lomshini wokupakisha usimende onamayunithi amaningi okugcwalisa, ongagcwalisa ngobuningi usimende noma izinto ezifanayo eziyimpushana esikhwameni sembobo ye-valve, futhi iyunithi ngayinye ingajikeleza i-axis efanayo ohlangothini oluvundlile.

Lo mshini osebenzisa ukulawula isivinini sokuguqula imvamisa yesistimu yokuzungeza eyinhloko, isakhiwo esijikelezayo sokuphakelayo esimaphakathi, umshini wokulawula okuzenzakalelayo owenziwe ngomshini nokagesi kanye nedivayisi yokulinganisa ezenzakalelayo ye-microcomputer. Ngaphezu kokufaka isikhwama ngesandla, okokusebenza kungenza ngokuzenzakalelayo ukucindezelwa kwesikhwama sikasimende, ukuvulwa kwebhodi lesango, ukugcwaliswa kukasimende nokukhishwa kwesikhwama.

Isakhiwo somshini wokupakisha usimende we-rotary

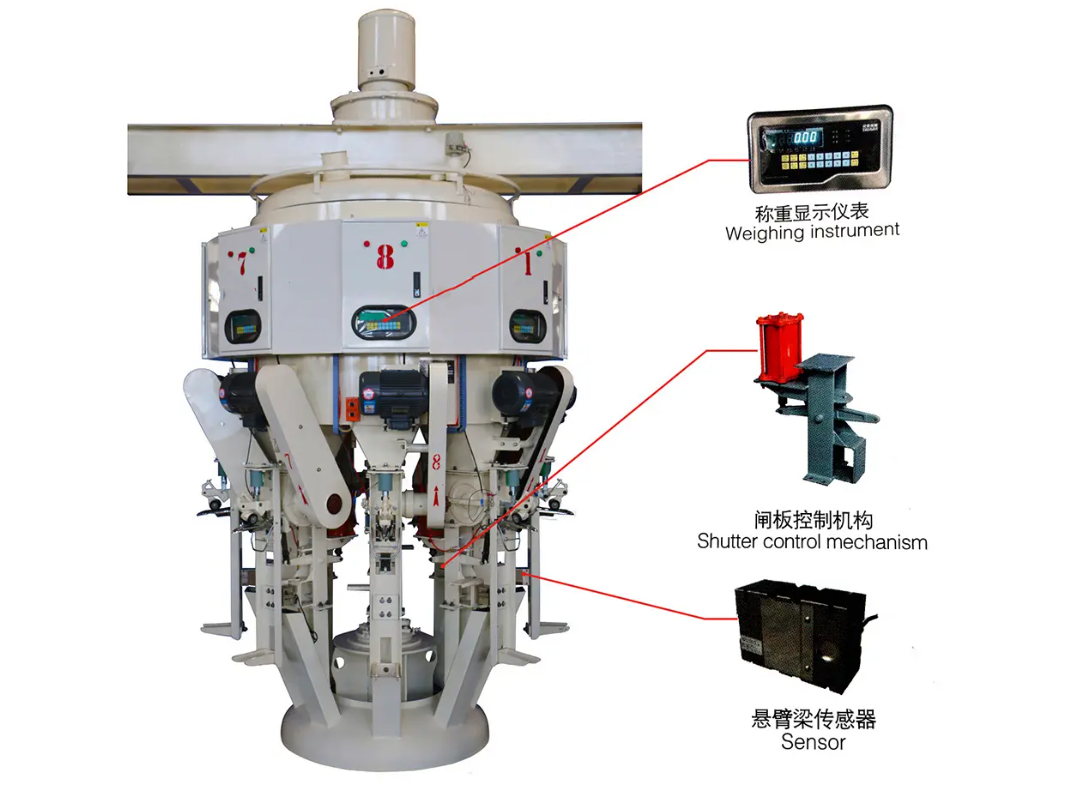

Umshini wokupakisha usimende wakhiwe ngokuyinhloko umzimba womshini, idivayisi yokondla, idivayisi yokukhipha impahla, iKhabhinethi yokulawula, idivayisi yesisindo sekhompyutha encane kanye nedivaysi yokulenga isikhwama. I-fuselage iyisakhiwo sensimbi esishiselwe ngamandla amakhulu, ukuqina okuphezulu.

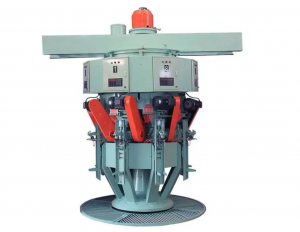

1. Idivayisi yokudla: isinciphisi se-cycloidal pinwheel sishayela i-sprocket encane, futhi iketango ne-sprocket enkulu ishayela isiphakeli ukuthi sijikelezise ukuze kuqedwe.

2. Idivaysi yokukhipha izinto ezibonakalayo: injini ishayela i-impeller yokuphotha ukuze ijikeleze, i-impeller ejikelezayo ikhipha usimende, futhi usimende ulayishwa esikhwameni sokupakisha ngepayipi elikhiphayo.

3. Ikhabhinethi yokulawula: iqalwa ngokushintsha kokuhamba, futhi isilinda silawulwa yi-microcomputer kanye ne-solenoid valve ukuze uvule umlomo wokukhipha futhi uqaphele ukulawulwa okuzenzakalelayo okuhlanganisiwe kwezinto zikagesi.

4. Idivayisi yokukala ye-Microcomputer: umshini wokupakisha wamukela isisindo se-microcomputer, esibonakala ngokulungiswa okulula kanye nesisindo sesikhwama esizinzile.

5. Idivayisi yokulahla isikhwama: Inomshini wokulahla isikhwama oyingqayizivele nenoveli. Lapho usimende ulayishwa esisindweni esilinganiselwe, i-nozzle yokukhipha ivaliwe, futhi ukugcwaliswa kumisiwe. Ngesikhathi esifanayo, i-electromagnetic idonsa ngesignali ye-inductor. Idivayisi yokucindezela isikhwama iyasebenza, futhi idivayisi yokuwisa isikhwama ezenzakalelayo iyasebenza. Isikhwama sikasimende siyawa, sitshekele ngaphandle, sishiye umshini wokupakisha.

Imingcele yezobuchwepheshe

| Imodeli | I-Spout | Amandla Wokuklama (t/h) | Isisindo sesikhwama esisodwa (kg) | Isivinini Esizungezayo (r/min) | Ivolumu Yomoya Ecindezelwe (m3/h) | Ingcindezi (Mpa) | Uthuli Oluqoqa Ivolumu Yomoya (m3/h) |

| I-DCS-6S | 6 | 70 ~ 90 | 50 | 1.0 ~ 5.0 | 90 ~ 96 | 0.4 ~ 0.6 | 15000 |

| I-DCS-8S | 8 | 100 ~ 120 | 50 | 1.3 ~ 6.8 | 90 ~ 96 | 0.5 ~ 0.8 | 22000 |

Umgomo wokusebenza womshini wokupakisha usimende:

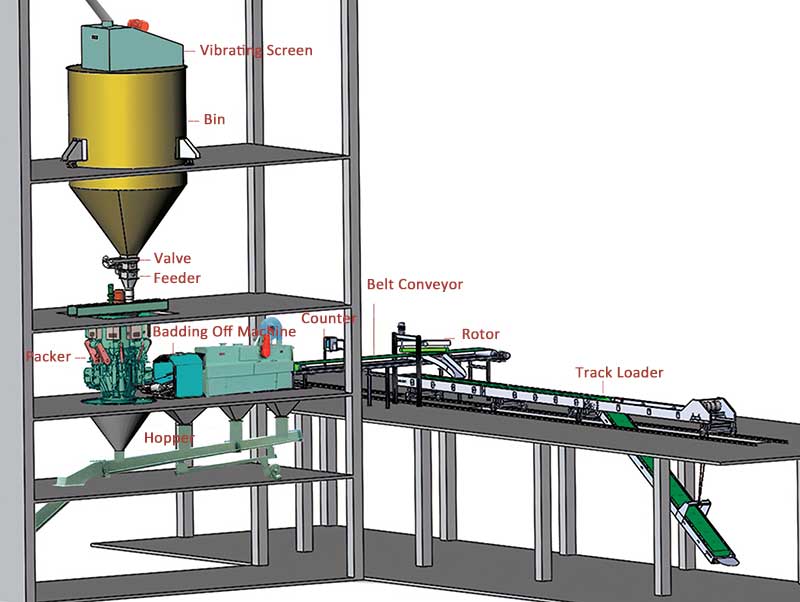

Usimende ku-silo ufaka i-hopper yomshini wokupakisha usimende, futhi lapho ufaka izikhwama ngesandla, qalisa ukushintshwa kohambo ukuze udlulisele isignali ku-microcomputer, qala i-valve ye-solenoid, sebenzisa isilinda, vula umlomo wombhobho, futhi i-impeller enesivinini esikhulu izoqhubeka igcwalisa usimende esikhwameni sezinto ezibonakalayo ngokusebenzisa i-nozzle yokukhipha. Lapho isisindo sesikhwama sifinyelela inani elibekiwe, inzwa izodlulisela isignali ku-microcomputer, futhi i-valve ye-solenoid izoqala isilinda ngokusebenzisa isilawuli se-microcomputer, Vala i-nozzle yokukhipha ukuze ugcwalise ngokwezifiso; Ngesikhathi esifanayo, i-valve ye-solenoid idonsa ngesignali ye-inductor, futhi idivayisi yokucindezela isikhwama yenza ngokuzenzakalelayo ukutshekisa isikhwama bese usilahla. Yonke inqubo yokugcwalisa ilawulwa ngogesi. Ngaphandle kokufaka isikhwama ngesandla, ukuvulwa nokuvalwa kwesikhwama sikasimende esicindezelayo kanye nokukhipha umlomo wombhobho; Ukugcwaliswa kwesikhwama sikasimende, ukukala kanye nemitha, ukwehla kwesikhwama okuzenzakalelayo neminye imisebenzi kungaqedwa ngokuzenzakalelayo, ukuze kuncishiswe ukwehluleka kwemishini nokuqinisekisa ukusebenza kahle kwemishini yokupakisha.

Izinzuzo:

1. Ukusebenza okuzinzile, nciphisa ukudlidliza okuguquguqukayo futhi udale izimo ezinhle zokulinganisa nokukala.

2. Isakhiwo esihlangene, ukondla okuphakathi komshini wokupakisha usimende kulungele ama-circuits kagesi ukuze ahlelwe ngaphandle kwe-silo ejikelezayo, ama-circuits akulula ukushisa, kulula ukuwagcina.

3. Izicelo ezibanzi, faka impuphu noma izinto eziyizinhlayiyana ezinoketshezi oluhle.

4. Okuzenzakalelayo okuzenzakalelayo, ngokuyisisekelo qaphela i-automation, ukugcwalisa, i-metering, ukuwisa isikhwama, nezinye izenzo ziqedwa isethi eyodwa yesitshalo sokupakisha usimende ngokuzenzakalelayo nangokuqhubekayo.

5. Indawo yokusebenza ehlanzekile futhi enobungani nemvelo, uma isisindo sesikhwama singaphansi kwenani elishiwo, isikhwama ngeke sehle. Uma isikhwama siwela ngokungalindelekile, isango lizovalwa ngokushesha futhi ukugcwaliswa kuzoyeka.

6. Ukugcinwa okulula, izingxenye ezisengozini encane, azikho i-hydraulic, izingxenye ze-pneumatic.

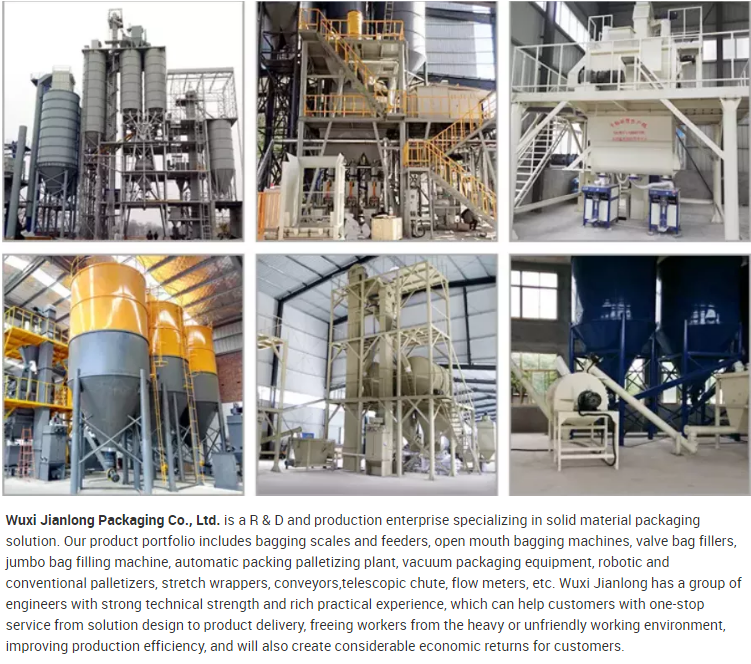

Iphrofayela Yenkampani

UMnu. Yark

Whatsapp: +8618020515386

UMnu. Alex

Whatsapp:+8613382200234