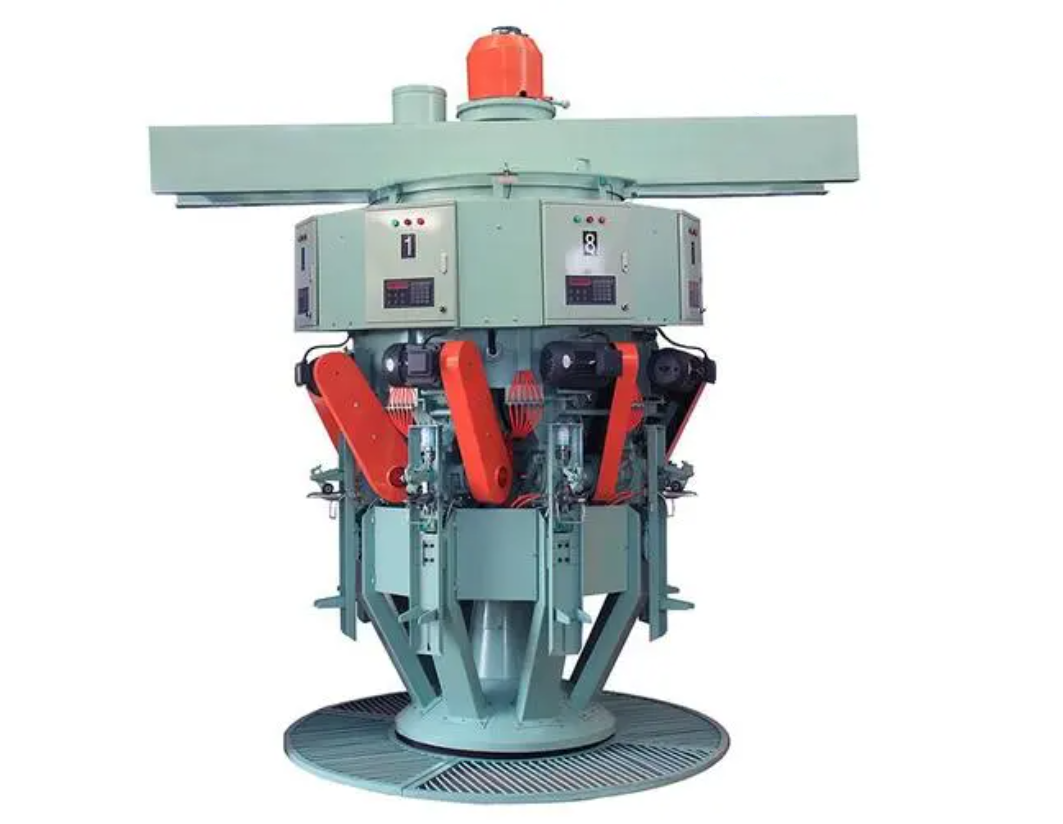

Umshini Wokugcwalisa Umshini Wokugcwalisa Umshini Wokugcwalisa I-Mortar Powder Valve

Incazelo yomkhiqizo

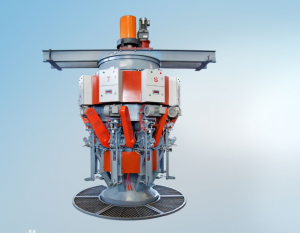

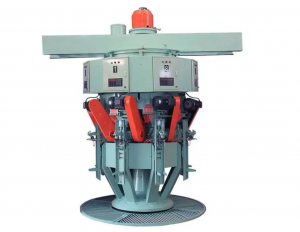

Umshini wokupakisha usimende ojikelezayo we-DCS uwuhlobo lomshini wokupakisha usimende onamayunithi amaningi okugcwalisa, ongagcwalisa ngobuningi usimende noma izinto ezifanayo eziyimpushana esikhwameni sembobo ye-valve, futhi iyunithi ngayinye ingajikeleza i-axis efanayo ohlangothini oluvundlile.

Lo mshini osebenzisa ukulawula isivinini sokuguqula imvamisa yesistimu yokuzungeza eyinhloko, isakhiwo esijikelezayo sokuphakelayo esimaphakathi, umshini wokulawula okuzenzakalelayo owenziwe ngomshini nokagesi kanye nedivayisi yokulinganisa ezenzakalelayo ye-microcomputer. Ngaphezu kokufaka isikhwama ngesandla, okokusebenza kungenza ngokuzenzakalelayo ukucindezelwa kwesikhwama sikasimende, ukuvulwa kwebhodi lesango, ukugcwaliswa kukasimende nokukhishwa kwesikhwama.

Isakhiwo somshini wokupakisha usimende we-rotary

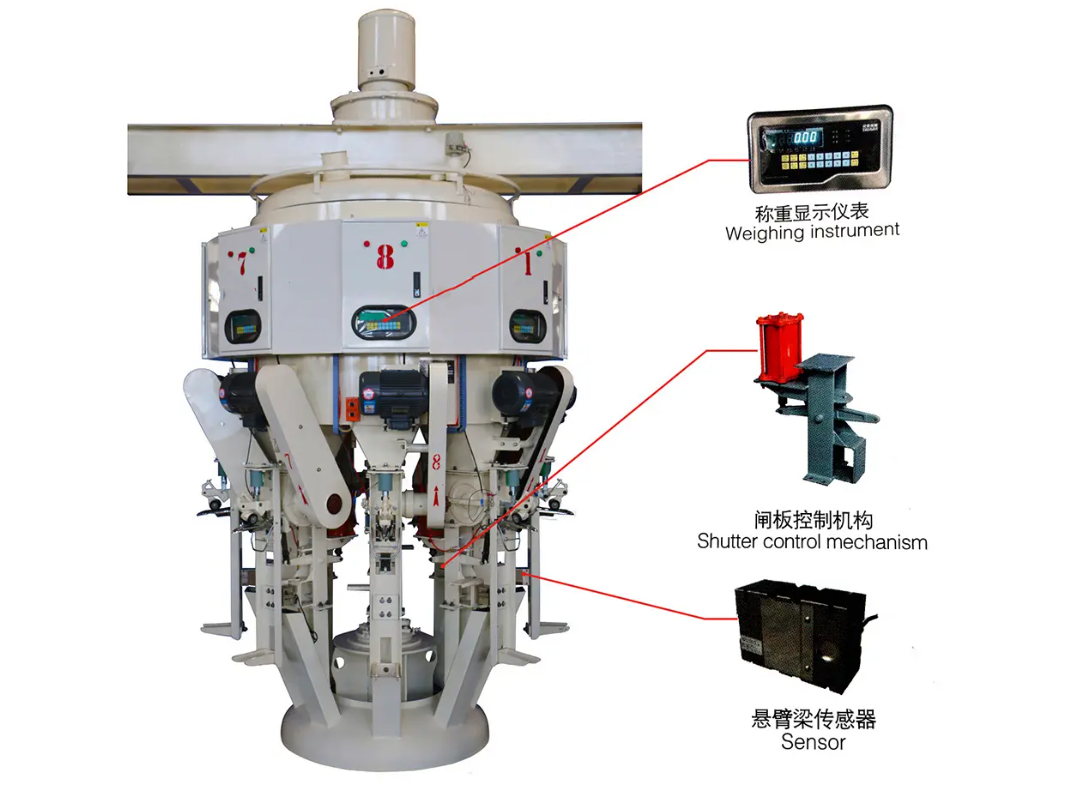

Umshini wokupakisha usimende wakhiwe ngokuyinhloko umzimba womshini, idivayisi yokondla, idivayisi yokukhipha impahla, iKhabhinethi yokulawula, idivayisi yesisindo sekhompyutha encane kanye nedivaysi yokulenga isikhwama. I-fuselage iyisakhiwo sensimbi esishiselwe ngamandla amakhulu, ukuqina okuphezulu.

1. Idivayisi yokudla: isinciphisi se-cycloidal pinwheel sishayela i-sprocket encane, futhi iketango ne-sprocket enkulu ishayela isiphakeli ukuthi sijikelezise ukuze kuqedwe.

2. Idivaysi yokukhipha izinto ezibonakalayo: injini ishayela i-impeller yokuphotha ukuze ijikeleze, i-impeller ejikelezayo ikhipha usimende, futhi usimende ulayishwa esikhwameni sokupakisha ngepayipi elikhiphayo.

3. Ikhabhinethi yokulawula: iqalwa ngokushintsha kokuhamba, futhi isilinda silawulwa yi-microcomputer kanye ne-solenoid valve ukuze uvule umlomo wokukhipha futhi uqaphele ukulawulwa okuzenzakalelayo okuhlanganisiwe kwezinto zikagesi.

4. Idivayisi yokukala ye-Microcomputer: umshini wokupakisha wamukela isisindo se-microcomputer, esibonakala ngokulungiswa okulula kanye nesisindo sesikhwama esizinzile.

5. Idivayisi yokulahla isikhwama: Inomshini wokulahla isikhwama oyingqayizivele nenoveli. Lapho usimende ulayishwa esisindweni esilinganiselwe, i-nozzle yokukhipha ivaliwe, futhi ukugcwaliswa kumisiwe. Ngesikhathi esifanayo, i-electromagnetic idonsa ngesignali ye-inductor. Idivayisi yokucindezela isikhwama iyasebenza, futhi idivayisi yokuwisa isikhwama ezenzakalelayo iyasebenza. Isikhwama sikasimende siyawa, sitshekele ngaphandle, sishiye umshini wokupakisha.

Imingcele yezobuchwepheshe

| Imodeli | I-Spout | Amandla Wokuklama (t/h) | Isisindo sesikhwama esisodwa (kg) | Isivinini Esizungezayo (r/min) | Ivolumu Yomoya Ecindezelwe (m3/h) | Ingcindezi (Mpa) | Uthuli Oluqoqa Ivolumu Yomoya (m3/h) |

| I-DCS-6S | 6 | 70 ~ 90 | 50 | 1.0 ~ 5.0 | 90 ~ 96 | 0.4 ~ 0.6 | 15000 |

| I-DCS-8S | 8 | 100 ~ 120 | 50 | 1.3 ~ 6.8 | 90 ~ 96 | 0.5 ~ 0.8 | 22000 |

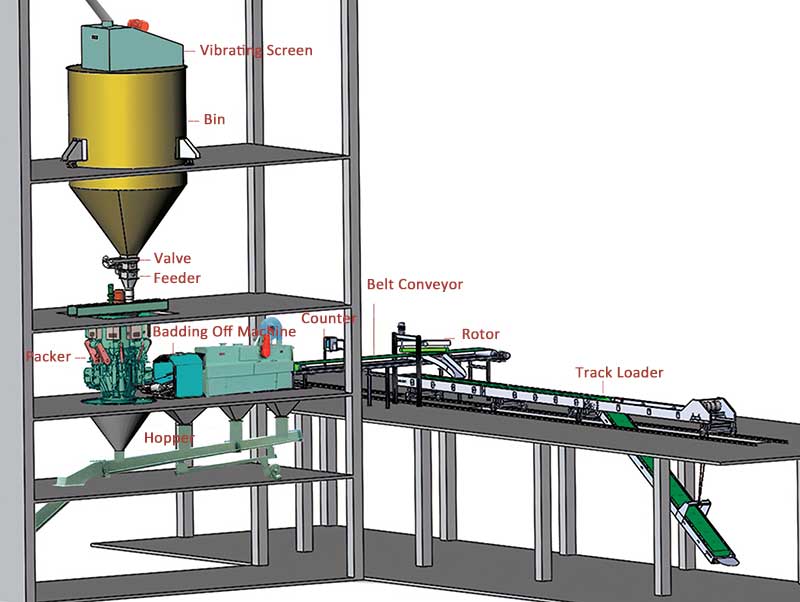

Umgomo wokusebenza womshini wokupakisha usimende:

Usimende ku-silo ufaka i-hopper yomshini wokupakisha usimende, futhi lapho ufaka izikhwama ngesandla, qalisa ukushintshwa kohambo ukuze udlulisele isignali ku-microcomputer, qala i-valve ye-solenoid, sebenzisa isilinda, vula umlomo wombhobho, futhi i-impeller enesivinini esikhulu izoqhubeka igcwalisa usimende esikhwameni sezinto ezibonakalayo ngokusebenzisa i-nozzle yokukhipha. Lapho isisindo sesikhwama sifinyelela inani elibekiwe, inzwa izodlulisela isignali ku-microcomputer, futhi i-valve ye-solenoid izoqala isilinda ngokusebenzisa isilawuli se-microcomputer, Vala i-nozzle yokukhipha ukuze ugcwalise ngokwezifiso; Ngesikhathi esifanayo, i-valve ye-solenoid idonsa ngesignali ye-inductor, futhi idivayisi yokucindezela isikhwama yenza ngokuzenzakalelayo ukutshekisa isikhwama bese usilahla. Yonke inqubo yokugcwalisa ilawulwa ngogesi. Ngaphandle kokufaka isikhwama ngesandla, ukuvulwa nokuvalwa kwesikhwama sikasimende esicindezelayo kanye nokukhipha umlomo wombhobho; Ukugcwaliswa kwesikhwama sikasimende, ukukala kanye nemitha, ukwehla kwesikhwama okuzenzakalelayo neminye imisebenzi kungaqedwa ngokuzenzakalelayo, ukuze kuncishiswe ukwehluleka kwemishini nokuqinisekisa ukusebenza kahle kwemishini yokupakisha.

Izici:

1.Isikulufa somshini wokupakisha usimende;

2.Yehlisa uthuli kanye nomshini wokupakisha imvelo

3.Imisebenzi yokugcwalisa inani lokungeniswa okuzenzakalelayo

4.Ukubala okuzenzakalelayo nokubonisa imisebenzi

5.Umsebenzi wokukhipha isikhwama ngokuzenzakalelayo.

Imilomo yokugcwalisa uhlobo lwe-Valve.

7.Isistimu yokukala enembile

Isithombe esinemininingwane

Ezinye izinto ezisizayo

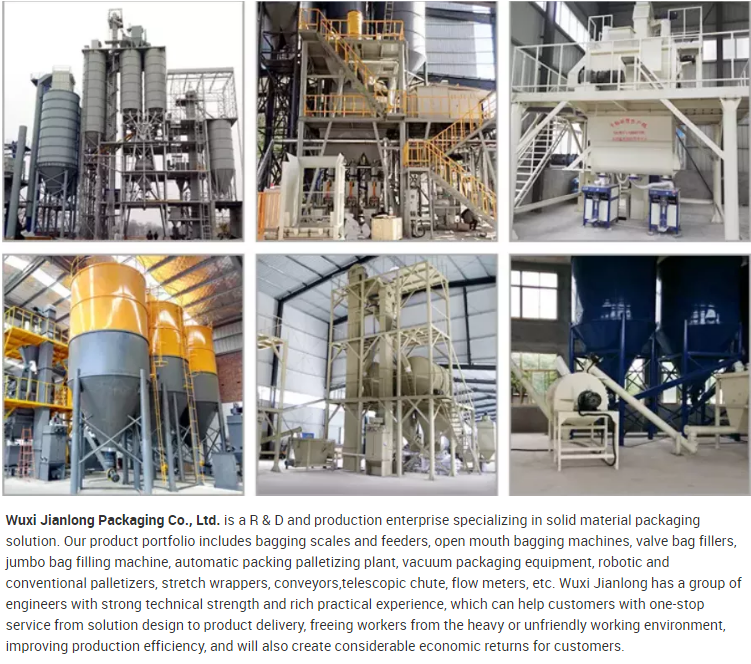

Mayelana NATHI

UMnu. Yark

Whatsapp: +8618020515386

UMnu. Alex

Whatsapp:+8613382200234