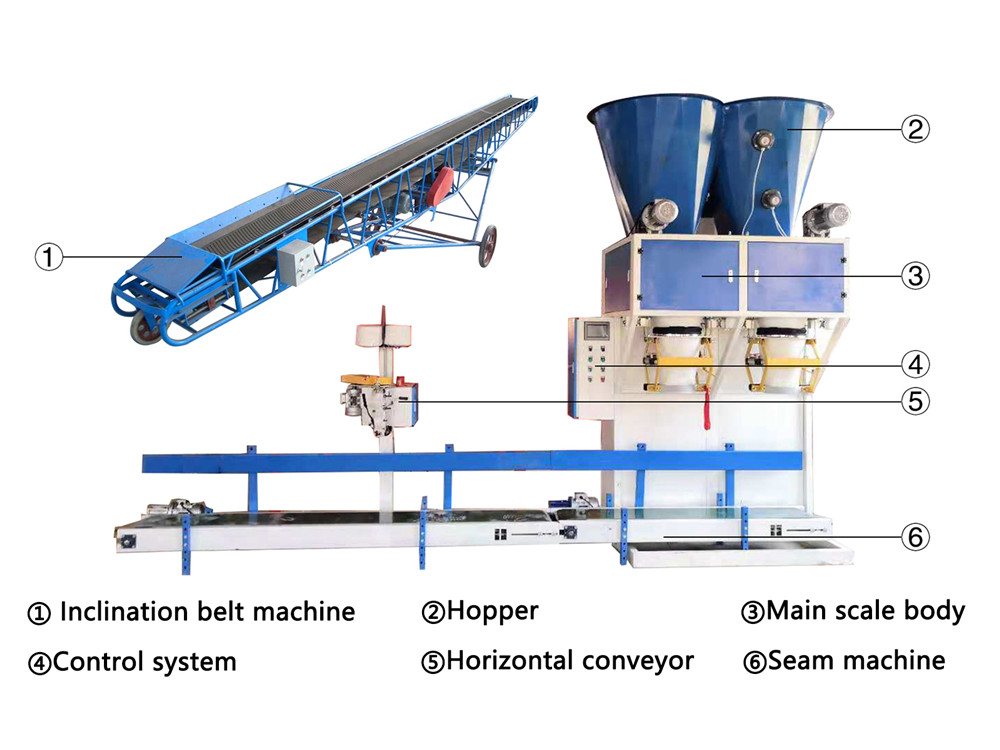

Automatic Fertilizer Weigh Feeder Filling System Automated Bagging Scales For Animal Feed

Pellet packaging machine/ wood pellets package machine can measure weight and pack bags automatically, there is weight sensor and adjuster on packing machine , when adjust weight into one stable number for example 15 kg/bag, bags will fall down automatically when reaches 15 kg and along heat sealing machine conveyor into sealing parts. But when bags fall down to bottom conveyor, needs one person to hand it to make sure it will not oblique and pour out pellets.

Features

1. Speed Packaging , High precision, Digital display,

Intuitive and easy to read, Simple manual operation, Strong environmental adaptability

2. High reliability:

Main components of the control system are SIEMENS and SCHNEIDER products;

The pneumatic system mainly adopts AIRTAC and FESTO products

3. Reasonable mechanical structure:

obtained a number of national patents, good system maintenance-free, material adaptability;

The part in contact with the material is 304 stainless steel

The equipment covers a small area, convenient and flexible installation, adjustable speed, fast and slow feeding through the controller to view, easy cleaning and maintenance

4. Packaging Material:

Powder material with good fluidity (Premix fertilizer, flour, starch, feed, silica powder, aluminum oxide, etc.)

Specification

| Model | DCS-GF | DCS-GF1 | DCS-GF2 |

| Weighing Range | 1-5, 5-10, 10-25, 25-50 Kg/bag, customized needs | ||

| Precision | ±0.2%FS | ||

| Packing Capacity | 200-300 bag/hour | 250-400 bag/hour | 500-800 bag/hour |

| Power supply | 220 V/380 V, 50 HZ, 1 P/3 P ( Customized) | ||

| Power (KW) | 3.2 | 4 | 6.6 |

| Dimension (LxWxH) mm | 3000 x 1050 x 2800 | 3000 x 1050 x 3400 | 4000 x 2200 x 4570 |

| The size can be customized according to your site. | |||

| Weight | 700 kg | 800 kg | 1600 kg |

The above parameters are only for your reference, the manufacturer reserves the right to modify the parameters with the development of the technology.

Product pictures

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatsapp:+8613382200234