The gravel packaging world is a well understood industry by Wuxi Jianlong (Wuxi Jianlong), as we offer a large selection of gravel bagging machines, palletizers and pallet wrapping machines. Typical gravel bagging lines are equipped with a volumetric feeder to measure the accurate volume of product to put in each bag, an FFS bagging machine, a conventional bag palletizer, and a pallet wrapping machine. If you are not looking for an automatic solution, Wuxi Jianlong can provide you a semi-automatic gravel bagging machines. Wuxi Jianlong also offers bagging scales that can be used with FFS or manual bagging machines.

Wuxi Jianlong can help you to either automate the full packaging line or a specific segment. No matter the scope of your project, Wuxi Jianlong manufactures gravel bagging machines for small-, medium- and large-scale productions.

See below the different gravel bagging machines we offer. For more information, just click on any product that you are interested in.

Bagging

Semi automatic bagging machine

-

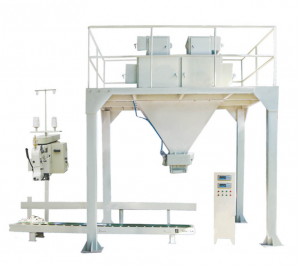

Duplex Gravity Open Mouth Bag Filling Scale, Net weight gravity packing scale,Duplex Gravity Filler DCS-GF2

Duplex Gravity Filler is suitable for granular materials and some powders with particularly good fluidity in industries such as chemical industry, food, feed, plastics, building materials, seeds, fertilizers, granular compound fertilizers, soups, washing powder, sugar. Granules quantitative packaging scale is mainly equipped with weighing mechanism, feeding mechanism, body frame, control system, conveyor and sewing machine, etc.Model

DCS-GF

DCS-GF1

DCS-GF2Weighing Range

1-5, 5-10, 10-2... -

Granules packaging machine, open mouth bagging machine, granule bag filler DCS-GF1

Working principle

The granule packaging machine with single hopper needs to manually wear the bag, manually put the bag on the discharging spout of the packing machine, toggle the bag clamping switch, and the control system will drive the cylinder after receiving the bag clamping signal to drive the bag clamp to clamp the bag and start feeding at the same time The mechanism sends the material in the silo into the weighing hopper. After reaching the target weight, the feeding mechanism stops ... -

Granules bagging machine, granules open mouth bagger, pellet packaging machine DCS-GF

Our company produces granules bagging machine DCS-GF, which is a fast quantitative packaging unit integrating weighing, sewing, packaging and conveying, which has been welcomed by the majority of users for many years. It is widely used in light industry, chemical industry, metallurgy, building materials, port, mining, food, grain and other industries.

Working principle

DCS-GF granules bagging machine needs manual bag loading. The bag is put on the discharging port of the bagger manually, an... -

Potato bagging scale

Main feature:

The packaging machine can quickly measure and bag tuber vegetables including potatoes, onions, and garlic. The mechanical structure is strong, stable and reliable. It is especially suitable for the continuous weighing and packaging solution for tuber vegetables such as potatoes , onions,sweet potato in the agricultural industry; briquettes and ore in the mineral industry to ensure the measurement accuracy. There are anti-blocking, anti-collision and anti-blocking devices inside...

Automatic bagging machine

-

DCS-5U Fully Automatic bagging machine,automatic weighing and filling machine

Technical Features:

1. The system can be applied to paper bags, woven bags, plastic bags and other packaging materials. It is widely used in chemical industry, feed, grain and other industries.

2. It can be packed in bags of 10kg-20kg, with a maximum capacity of 600 bags/hour.

3. Automatic bag feeding device adapts to high-speed continuous operation.

4. Each executive unit is equipped with control and safety devices to realize automatic and continuous operation.

5. Using SEW motor drive d...

Jumbo bagging machine

-

Bulk bag loader, bulk filler, bulk bag filling equipment

Bulk bag loader is specialized for automatic packaging of powder and granular materials of ton bag, with high degree of automation. It has the functions of automatic filling, automatic bagging, automatic decoupling, which greatly reduces the labor cost and labor intensity.

Main features:

The structure is simple and not easy to be damaged.

High degree of automation, automatic decoupling, reduce the operation of workers.

Automatic bag patting function to improve loading capacity and packing ... -

Bulk bagging machine, big bag filler,sack filling machine

Bulk bagging machine, also known as big bag filler and sack filling machine, is a special bulk material packaging equipment with unique structure and large packaging capacity, integrating weight display, packaging sequence, process interlocking, and fault alarm. It has the characteristics of high measurement accuracy, large packaging capacity, green sealant material, high degree of automation, large production capacity, large application range, simple operation, and easy installation. There a...

Palletizing

Robotic palletizers

-

Robotic arm palletizer, robotic palletising, robot palletizing system

The palletizing robot is mainly designed for palletizing applications. The articulated arm has a compact structure and can be integrated into a compact back-end packaging process. At the same time, the robot realizes the item handling through the swing of the arm, so that the previous incoming material and the following palletizing are connected, which greatly shortens the packaging time and improves the production efficiency.

The palletizing robot has extremely high precision, precise pick...

Conventional palletizers

-

High position palletizer,High position packaging and palletizing system

Working principle:

The main components of the automatic palletizer are: Summary conveyor, climbing conveyor, indexing machine, marshalling machine, layering machine, elevator, pallet warehouse, pallet conveyor, pallet conveyor and elevated platform, etc.

The fully automatic palletizer receives palletized products at a specific height or level above the pallet. Empty pallets are sent from a silo or accumulation station to the palletizer, the machine supports the pallets and positions them unde... -

Low position palletizer,low position packaging and palletizing system

The low position palletizer can work for 8 hours to replace 3-4 people, which saves the company’s labor cost every year. It has strong applicability and can realize multiple functions. It can encode and decode multiple lines on the production line, and the operation is simple. , People who have not operated before can get started with simple training. The packaging and palletizing system is small, which is conducive to the layout of the production line in the customer’s factory. The pal...