China Factory Automatic Pallet Stacker Robotic Palletizer

Introduction:

Robot automatic packing machine wide application range, cover an area of an area small, reliable performance, easy operation, can be widely used in food, chemical industry, medicine, salt and so on the various products of high-speed automatic packing production line, with motion control and tracking performance, very suitable for application in flexible packaging systems, greatly shorten the cycle time packing. According to the different product customization gripper.

Robot palletizing production line can be in accordance with the requirements of the organization mode and layer, complete the bags, boxes, barrels, plate etc. all kinds of packaging, palletizing, greatly improve production efficiency and save labor costs.

Robot palletizer is use for packing bags, cartons even other kinds products on one by one pallet. No problem make program to realize different pallet type according to your requirements.The palletizer will pack 1-4 angle pallet if you set. One palltizer is ok working along with one conveyor line, 2 conveyor line and 3 conveyor lines.Its optional.Mainly use in automotive, logistics, home appliances, pharmaceuticals, chemicals, food and beverages industries,etc.

Characteristic:

1. Simple structure, few parts, low failure rate and convenient maintenance.

2. It occupies less space, which is good to the layout of the production line and leaves a larger warehouse area.

3. Strong applicability. When the size, volume and shape of the product change, only need to be modify the parameters on the touch screen. Different grippers can be used to grab bags, barrels and boxes.

4. Low energy consumption and reduced operation cost

Parameters:

| Weighing range | 10-50 kg |

| Packing speed (bag/hour) | 100-1200 bag/hour |

| Air source | 0.5-0.7 Mpa |

| Working temperature | 4ºC-50ºC |

| Power | AC 380 V ,50 HZ, or customized according to the power supply |

Related equipment

Other auxiliary equipment

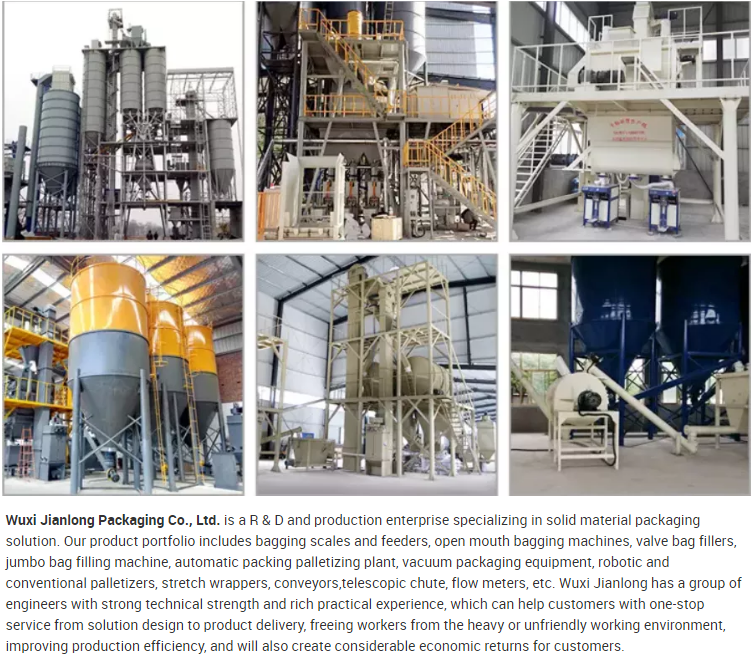

Company profile

Mr. Yark

Whatsapp: +8618020515386

Mr. Alex

Whatsapp:+8613382200234