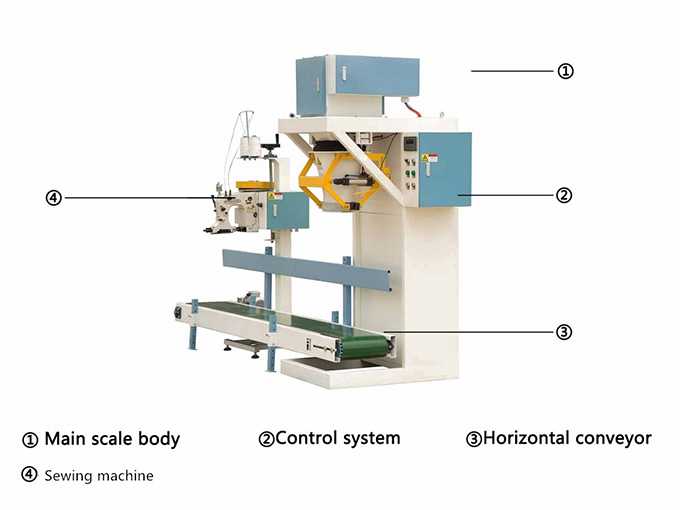

Granules bagging machine, granules open mouth bagger, pellet packaging machine DCS-GF

Product description:

Our company produces granules bagging machine DCS-GF, which is a fast quantitative packaging unit integrating weighing, sewing, packaging and conveying, which has been welcomed by the majority of users for many years. It is widely used in light industry, chemical industry, metallurgy, building materials, port, mining, food, grain and other industries.

Working principle

DCS-GF granules bagging machine needs manual bag loading. The bag is put on the discharging port of the bagger manually, and the bag clamping switch is turned on. After receiving the bagging signal, the control system drives the cylinder, and the bag gripper clamps the bag. At the same time, the feeding mechanism is started to send the materials from the silo to the packaging scale. The feeder is of gravity feeding mode. When the target weight is reached, the feeding mechanism stops and the bag clamping device opens automatically, The package bag falls onto the conveyor automatically, and the conveyor transports the bag to the sewing machine. After the sewing and sealing, the bag is output backward to complete a bagging process.

Functional features

1.Manual assistance is needed for bag loading, automatic weighing, bag clamping, filling, automatic conveying and sewing;

2.Gravity feeding mode is adopted to ensure the bagging speed and accuracy through instrument control;

3.It adopts high precision sensor and intelligent weighing controller, with high precision and stable performance;

4.The parts in contact with materials are made of stainless steel with high corrosion resistance;

5.Electrical and pneumatic components are imported components, long service life and high stability;

6.The control cabinet is sealed and suitable for harsh dust environment;

7.Material out of tolerance automatic correction, zero point automatic tracking, overshoot detection and suppression, over and under alarm;

8.Optional automatic sewing function: photoelectric induction automatic sewing after pneumatic thread cutting, saving labor.

Video:

Video:

Applicable materials:

Technical Parameter:

| Model | DCS-GF | DCS-GF1 | DCS-GF2 |

| Weighing Range | 1-5, 5-10, 10-25, 25-50 Kg/bag, customized needs | ||

| Precisions | ±0.2%FS | ||

| Packing Capacity | 200-300bag/hour | 250-400bag/hour | 500-800bag/hour |

| Power supply | 220V/380V, 50HZ, 1P/3P ( Customized) | ||

| Power (KW) | 3.2 | 4 | 6.6 |

| Dimension (LxWxH)mm | 3000x1050x2800 | 3000x1050x3400 | 4000x2200x4570 |

| The size can be customized according to your site. | |||

| Weight | 700kg | 800kg | 1600 |

Products pictures:

Our Configuration:

Production Line:

Contact:

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatapp:+8613382200234