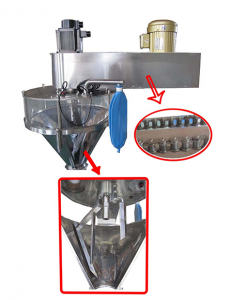

high accuracy semi-automatic auger filler 1kg 5kg flour rice powder cement fine bag pouch powder weighing filling machine

Brief introduction

DCS-VSF Fine powder bag filler is mainly developed and designed for the ultra-fine powder and and it can meet the high-precision packaging requirements. It is suitable for talcum powder, white carbon black, active carbon, putty powder and other ultra-fine powder.

Technical parameters

Measurement method: vertical screw double speed filling

Filling weight: 10-25kg

Packaging accuracy: ± 0.2%

Filling speed: 1-3 bags / min

Power supply: 380V (three-phase five wire), 50 / 60Hz

Overall power: 4kw

Power supply: AC220V / 380V ± 10%, 50Hz (three-phase five wire)

Air source: clean compressed air, pressure 0.6-0.8mpa, gas consumption 0.2nm3/min

Operating weight: 350kg

Total volume: 1000x850x3300mm or customization

German Siemens PLC and Siemens touch screen control

The weighing sensor adopts METTLER TOLEDO brand, which makes the weighing more accurate

Equipped with dedusting interface

Details

About us

Wuxi Jianlong Packaging Co., Ltd. is a R & D and production enterprise specializing in solid material packaging solution. Our product portfolio includes bagging scales and feeders, open mouth bagging machines, valve bag fillers, jumbo bag filling machine, automatic packing palletizing plant, vacuum packaging equipment, robotic and conventional palletizers, stretch wrappers, conveyors,telescopic chute, flow meters, etc. Wuxi Jianlong has a group of engineers with strong technical strength and rich practical experience, which can help customers with one-stop service from solution design to product delivery, freeing workers from the heavy or unfriendly working environment, improving production efficiency, and will also create considerable economic returns for customers.

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatsapp:+8613382200234