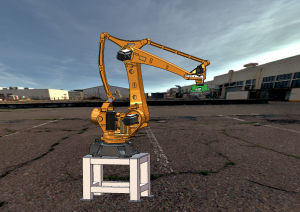

High Speed Robotic Palletizer Palletizing and Picking Robot

Introduction:

Robot palletizer can be integrated in any production line to provide intelligent, robotic and networked production site. It can realize palletizing logistics of various operations in beer, beverage and food industries. It is widely used in cartons, plastic boxes, bottles, bags, barrels, membrane packaging products and filling products. It is matched with the three in one filling line to stack all kinds of bottles, cans, boxes and bags. The automatic operation of the palletizer is divided into automatic box feeding, box turning, sorting, stacking, stacking, lifting, supporting, stacking and discharging.

Characteristic:

1. Simple structure, few parts, low failure rate and convenient maintenance.

2. It occupies less space, which is good to the layout of the production line and leaves a larger warehouse area.

3. Strong applicability. When the size, volume and shape of the product change, only need to be modify the parameters on the touch screen. Different grippers can be used to grab bags, barrels and boxes.

4. Low energy consumption and reduced operation cost

5. The operation is simple, only the starting point and the placement point need to be located, and the teaching method is simple and easy to understand.

Parameters:

| Weighing range | 10-50 kg |

| Packing speed (bag/hour) | 100-1200 bag/hour |

| Air source | 0.5-0.7 Mpa |

| Working temperature | 4ºC-50ºC |

| Power | AC 380 V ,50 HZ, or customized according to the power supply |

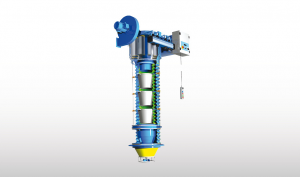

Related equipment

Other auxiliary equipment

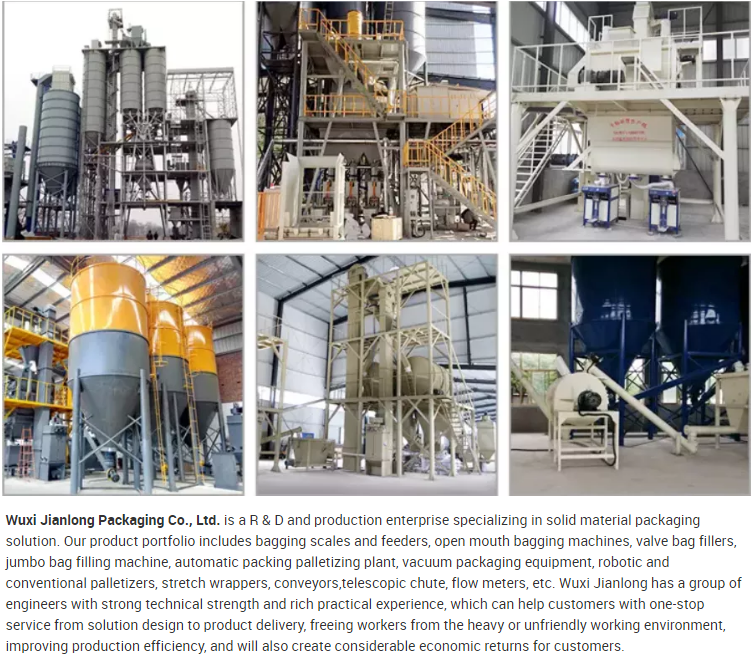

Company profile

Mr. Yark

Whatsapp: +8618020515386

Mr. Alex

Whatsapp:+8613382200234