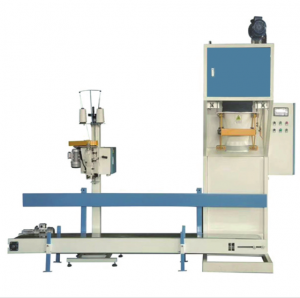

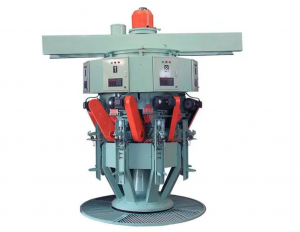

Semi-Auto 25kg 15kg Cube Charcoal Vegetable Weighing Packing Machine

Brief introduction

The bagging scale is specially designed for automatic quantitative weighing and packaging solutions for all kinds of machine-made carbon balls and other irregular shaped materials. The mechanical structure is strong, stable and reliable. It is especially suitable for continuous weighing of irregular shaped materials such as briquettes, coals, log charcoal and machine-made charcoal balls. The unique combination of feeding method and feeding belt can effectively avoid damage and prevent blocking and ensure the high accuracy. Easy maintenance and simple structure.

The equipment has novel structure, reasonable precision control, fast speed and high output, which is especially suitable for coal manufacturers with an annual output of more than 100,000 tons.

Product pictures

Technical parameter

| Accuracy | + / – 0.5-1% (Less than 3 pcs material, depending on the material characteristics) |

| Single scale | 200-300 bags / h |

| Power supply | 220VAC or 380VAC |

| Power consumption | 2.5KW~4KW |

| Compressed air pressure | 0.4 ~ 0.6MPa |

| Air consumption | 1 m3 / h |

| Package range | 20-50kg/bag |

Details

Application

Some projects show

Company profile

Wuxi Jianlong Packaging Co., Ltd. is a R & D and production enterprise specializing in solid material packaging solution. Our product portfolio includes bagging scales and feeders, open mouth bagging machines, valve bag fillers, jumbo bag filling machine, automatic packing palletizing plant, vacuum packaging equipment, robotic and conventional palletizers, stretch wrappers, conveyors, telescopic chute, flow meters, etc. Wuxi Jianlong has a group of engineers with strong technical strength and rich practical experience, which can help customers with one-stop service from solution design to product delivery, freeing workers from the heavy or unfriendly working environment, improving production efficiency, and will also create considerable economic returns for customers.

Mr. Yark

Whatsapp: +8618020515386

Mr. Alex

Whatsapp:+8613382200234