2019 Good Quality China Semi-Automatic Powder Filling Machine/Small Auger Filling Machine

Our company has been concentrating on brand strategy. Customers’ pleasure is our greatest advertising. We also source OEM service for 2019 Good Quality China Semi-Automatic Powder Filling Machine/Small Auger Filling Machine, With superb service and quality, and an enterprise of foreign trade featuring validity and competitiveness, that will be trusted and welcomed by its clients and creates happiness to its employees.

Our company has been concentrating on brand strategy. Customers’ pleasure is our greatest advertising. We also source OEM service for China Powder Filler Machine, Dry Powder Filler, Corporate goal: Customers’ satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

Product description:

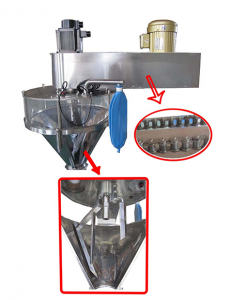

DCS-VSF Fine powder bag filler is mainly developed and designed for the ultra-fine powder and and it can meet the high-precision packaging requirements. It is suitable for talcum powder, white carbon black, active carbon, putty powder and other ultra-fine powder.

Video:

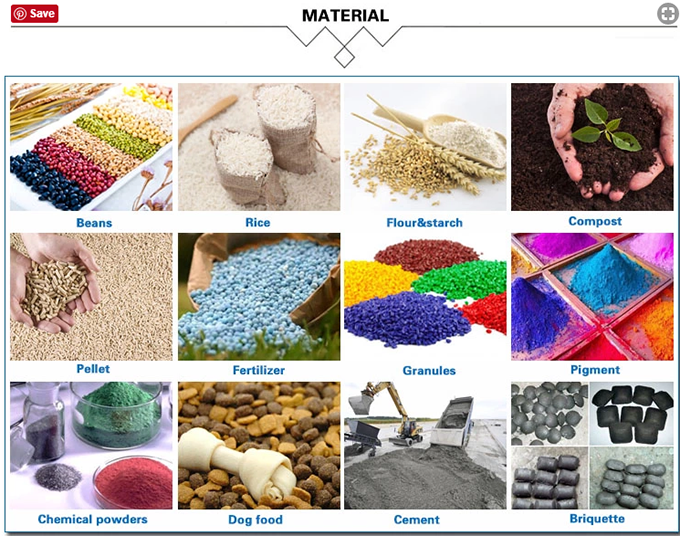

Applicable materials:

Technical Parameter:

Measurement method: vertical screw double speed filling

Filling weight: 10-25kg

Packaging accuracy: ± 0.2%

Filling speed: 1-3 bags / min

Power supply: 380V (three-phase five wire), 50 / 60Hz

Overall power: 4kw

Power supply: AC220V / 380V ± 10%, 50Hz (three-phase five wire)

Air source: clean compressed air, pressure 0.6-0.8mpa, gas consumption 0.2nm3/min

Operating weight: 350kg

Total volume: 1000x850x3300mm or customization

German Siemens PLC and Siemens touch screen control

The weighing sensor adopts METTLER TOLEDO brand, which makes the weighing more accurate

Equipped with dedusting interface

Products pictures:

Our Configuration:

Production Line:

Contact:

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatapp:+8613382200234