Ultrasonic sealing valve bag packing machine,Air Packer and ultrasonic valve bag sealer,valve bag filler Integrated Sonic Valve Sealer

Product description:

Valve bag filler with auto ultrasonic sealer is an environmentally-friendly packaging machine for ultra-fine powder, which is specially designed for automatic ultrasonic sealing of valve bag packaging in dry powder mortar, putty powder, cement, ceramic tile powder, chemical industry and other industries. The microcomputer system of the equipment is produced by industrial components and STM process. It has the advantages of strong function, high reliability and good adaptability. It integrates automatic weighing control, ultrasonic heat sealing and automatic bag unloading. It has unique anti-interference ability and can be used for a long time in harsh environment.

Video:

Main Structures:

1.Automatic filling system

2. Automatic weighing unit

3.Automatic packing unit

4.Automatic ultrasonic sealing unit

5.Electric control and Computer Control cabinet

Flowing Process:

Manual Bag placing→Automatic filling→ Automatic weighing→Automatic packing→Automtic unltrasonic sealing→Manual bag unloading

Technical Parameters:

Packing capacity: 3-5 bags / min (Note: different material packaging speed is different)

Weighing range: 15-25Kg/bag

Working power supply: 380V/50Hz (Or according to the customer’s requirement)

Working air source: Air pressure ≥0.5-07Mpa

Air consumption 0.2m3/min

Diameter of hopper:30cm

Standard dimensions: 1610mm×625mm×2050mm

Principle pictures:

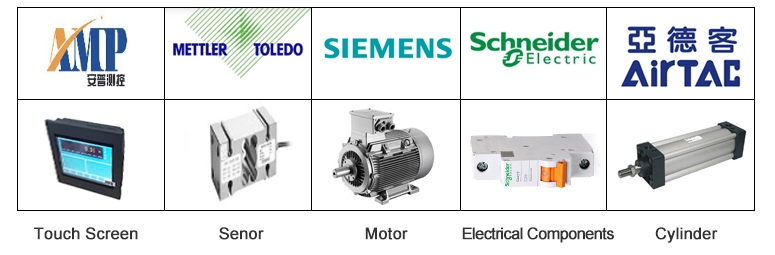

Our Configuration:

Contact:

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatapp:+8613382200234