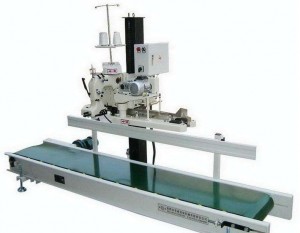

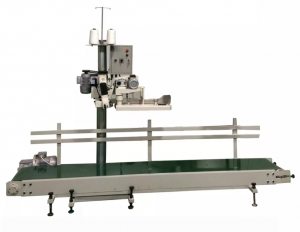

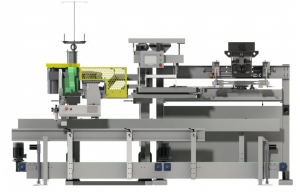

Sewing Machine Conveyor Automatic Bag Closing Conveyor

Product introduction:

The units have been supplied for either 110 volt/single phase, 220 volt/single phase, 220 volt/3 phase, 380/3 phase, or 480/3 phase power.

The conveyor system has been set up for either a one person operation or a two person operation according to the purchase order specifications. Both operating procedures are detailed as follows:

ONE PERSON OPERATIONAL PROCEDURE

This conveyor system is designed to work with a gross weigh bagging scale and is designed to close 4 bags per minute using one operator.

Operational Steps:

1. Hang bag #1 on the gross weigh bagging scale or on your existing scale and begin the fill cycle.

2. When the scale reaches weigh complete, drop bag #1 on the moving conveyor. The bag will move to the operators left until it strikes the wand switch, which will automatically stop the conveyor.

3. Hang bag #2 on the gross weigh bagging scale or on your existing scale and begin the fill cycle.

4. While the scale is automatically filling bag #2, snap the gusset closed on bag #1 and prepare it for sewing. The operator must make sure to keep the bag in contact with wand switch during this process; otherwise, the conveyor will automatically start.

5. Depress & hold the two position foot pedal approximately half way down (position #1). This will override the wand switch and start the conveyor moving. Just before the bag enters the sewing head, depress & hold the foot pedal all the way down (position #2). This will turn the sewing head on.

6. Once the bag is sewn, release the foot pedal. The sewing head will stop, but the conveyor will continue to run. Unless the unit is equipped with a pneumatic thread cutter, the operator must push the thread into the cutter blades on the sewing head in order to cut the sewing thread.

7. Place bag #1 on a pallet.

8. Return to gross weigh bagging scale and repeat steps 2 through 7.

TWO PERSON OPERATIONAL PROCEDURE

This conveyor system is designed to work with either a gross weigh bagging scale or a net weigh bagging scale using two operators.

Operational Steps:

1. Turn the conveyor on. The belt should be running from the operator’s right to left. The belt will run continuously during the operation. (If an emergency foot pedal has been provided, it can be used to stop the conveyor. If an emergency foot pedal has not been provided, the on/off switch located on the control box at the rear of the conveyor will be utilized for this purpose).

2. The first operator should hang bag #1 on the gross weigh bagging scale or on your existing scale and begin the fill cycle.

3. When the scale reaches weigh complete, drop bag #1 onto the moving conveyor. The bag will move to the operator’s left.

4. The first operator should hang bag #2 on the gross weigh bagging scale or on your existing scale and begin the fill cycle.

5. The second operator should snap the gusset closed on bag #1 and prepare it for closure. This operator should then start bag #1 into the bag closure device.

6. After the bag is closed, place the bag on a pallet and repeat steps 3 through 6.

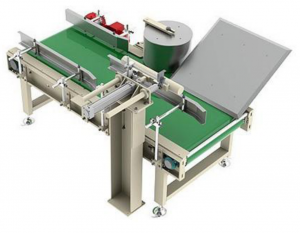

Other equipments