Valve bagging machine, valve bag filler,valve bag filling machine DCS-VBAF

Product description:

Valve bagging machine DCS-VBAF is a new type of valve bag filling machine that has accumulated more than ten years of professional experience, digested foreign advanced technology and combined with China’s national conditions. It has a number of patented technologies and has completely independent intellectual property rights. The machine adopts the most advanced low-pressure pulse air-floating conveying technology in the world, and completely uses low-pressure pulse compressed air to uniformly and horizontally convey the material on the ventilating device through a super-abrasion air-floating device with a certain angle, and the material passes through self-adjusting double The stroke gate valve controls the quick feeding and finishing of the material, and the automatic quantitative packaging of the material is completed through the ceramic discharge nozzle and the microcomputer plus the touch screen control. The packaging materials cover a wide range. All powders with a moisture content of less than 5% and a mixture of powder and aggregate (≤5mm) can be automatically packaged, such as industrial micropowder products, powdered pigments, powdered chemical products, flour and food. Additives, as well as ready-to-mix dry mortars (special mortars) of all varieties.

Video:

Applicable materials:

Technical Parameter:

1. Applicable materials: powder or granular materials with good fluidity

2. Material feeding method: gravity flow feeding

3. Weighing range: 5 ~ 50kg / bag

4. Packing speed: 150-200 bags / hour

5. Measurement accuracy: ± 0.1% ~ 0.3% (related to material uniformity and packaging speed)

6. Air source: 0.5 ~ 0.7MPa Gas consumption: 0.1m3 / min

7. Power supply: AC380V, 50Hz, 0.2kW

Products pictures:

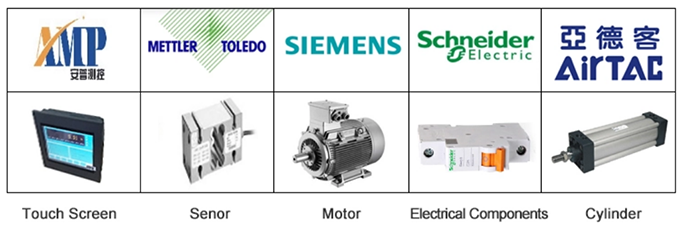

Our Configuration:

Contact:

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatapp:+8613382200234