Valve filling machine, valve bag packer ,valve type bag filling machine DCS-VBGF

Product description:

Valve filling machine DCS-VBGF adopts gravity flow feeding, which has the characteristics of high packaging speed, high stability and low power consumption.

Video:

Applicable materials:

1. Applicable materials: powder or granular materials with good fluidity

2. Material feeding method: gravity flow feeding

3. Weighing range: 5 ~ 50kg / bag

4. Packing speed: 150-200 bags / hour

5. Measurement accuracy: ± 0.1% ~ 0.3% (related to material uniformity and packaging speed)

6. Air source: 0.5 ~ 0.7MPa Gas consumption: 0.1m3 / min

7. Power supply: AC380V, 50Hz, 0.2kW

Products pictures:

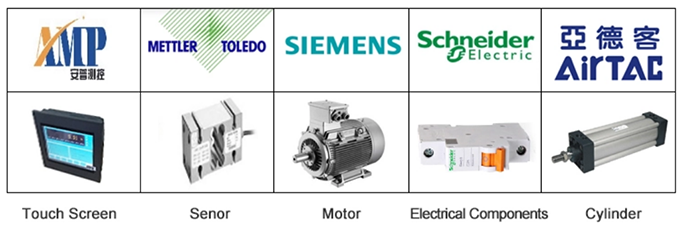

Our Configuration:

Contact:

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatapp:+8613382200234

Write your message here and send it to us