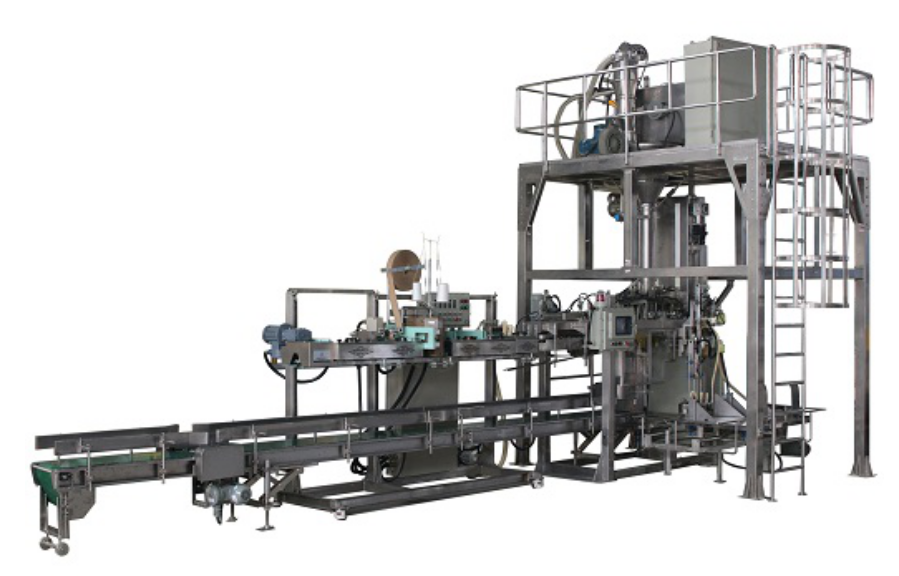

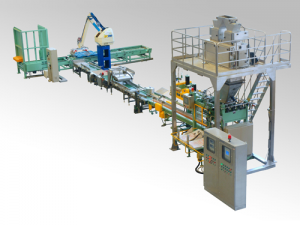

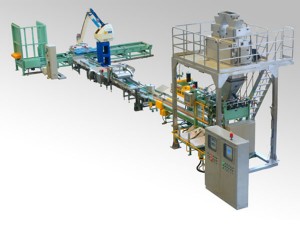

Bottom filling type fine powder degassing automatic packaging machine

1. Automatic bag feeding machine

Bag supply capacity: 300 bags / hour

It is pneumatic driven, and its bag library can store 100-200 empty bags. When the bags are about to be used up, an alarm will be given, and if all the bags are used up, the packaging machine will automatically stop working.

2. Automatic bagging machine

Bagging capacity: 200-350bags / h

main feature:

① Vacuum suction bag, manipulator bagging

② Alarm for lack of bags in the bag library

③ Alarm of insufficient compressed air pressure

④Bagging detection and bag blowing function

⑤The main parts are stainless steel

3. Vacuum bag taker

The vacuum suction cup separates and sucks the empty bags on the bag feeding machine, and the manipulator grips the empty bags and moves them to the middle of the bag feeding machine, then releases the gripper and returns to continue to take the bags.

4. Shaping and conveying device

After the shaping device centers the empty bag, the bag feeding device places the empty bag at a predetermined position and waits for bagging..

5. Bagging manipulator

After holding the empty bag on both sides, place the automatic bag holder.

6. Automatic bag clamp

The pneumatic gripper clamps the empty bag sent by the robot and checks whether it is clamped properly (if it is not clamped, the empty bag will be blown off automatically). Open the bag sucker to open the bag mouth, and at the same time check whether the bag mouth on the sucker is opened (if it is abnormal, blow out the empty bag).After normal operation, the discharge port shall be opened and extended into the bag port, and the electronic scale shall be informed to discharge, and the materials shall enter the packaging bag through the intermediate hopper.

7. Traverse trolley (push bag machine)

After the materials enter the packaging bag, the materials in the bag are fully overlapped, and then fed into the jaw shaping machine along the linear guide rail by the transverse trolley.

8. Bag mouth shaping machine

Together with the bag-delivery trolley, send the bag into the sealing unit to ensure that the bag mouth is not deformed. The height is mechanically adjustable, and the feeding speed is steplessly adjusted by frequency conversion.

Drive mode: AC motor, 380V ± 10%, 50HZ

Motor power: 0.37KW

9. Automatic packaging control system

Adopt imported controller, imported motor frequency conversion speed controller, imported photoelectricity and position detection device to form the main body of the control system, and realize the coordinated control of the whole packaging machine. The system has positive and negative pressure detection, and is equipped with automatic / manual conversion methods. The entire operating system is simple to use, has complete functions, and is properly overhauled and maintained.

Contact:

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatapp:+8613382200234