Dry mortar mixer plant production line cement mixer ceramic tile adhesive making machine equipment

Product description:

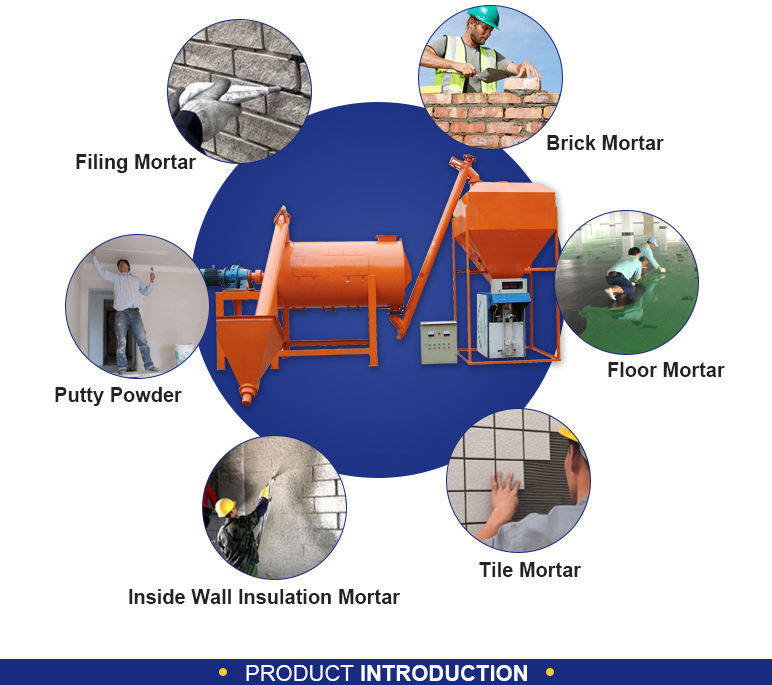

Introduction of dry mortar mixing machine

Dry mixing mortar machine, also known as pre-mixed mortar, is made in the factory by precise ingredients, mixing evenly.Construction site just add water can be directly used.Although different additives are added, they have different properties. Compared with the mortar produced on site, the demand for dry mortar increases rapidly because of its outstanding advantages.

Video:

Features of dry mortar mixing machine

1) Small investment, most suitable for individuals.

2) The area is small, and factories can be built in ordinary houses.

3) The operation is simple, and it can be completed by 2-3 people. .

4) The output is high, the output is generally 3-4T/H, reaching 20-25T/day.

5) Easy to operate and maintain.

Applications of dry mortar mixing machine

1) dry mortar

2) Insulation mortar

3) the putty powder

4) Masonry mortar

5) Thin and smooth wall mortar

6) Waterproof mortar

7) gypsum powder

8) Wall plastering mortar

9) Ceramic tile bonding mortar

MAIN CONFIGURATION

| No. | Name | Configuration | Function |

| 1 | Screw conveyor with hopper | Dia:Φ165X3500mm | Feeding material to mixer |

| 2 | Ribbon mixer | mixing time:10-15min/batch | to achieve uniform mixing effect in relatively short time. |

| 3 | Screw conveyor 2 | Dia:Φ165X3500mm | Convey the finished material to finished hopper from the mixer |

| 4 | End product hopper | Volume:1.5m³ | Store the finished material and prepare for the packing machine, which is improve the efficiency highly. |

| 5 | Packaging machine | Model: Valve type Rang: 15-50kg adjustable packing speed: 5-6s/bag. | automatic filling and packing machine. |

| 6 | Air compressor | balance the air pressure | |

| 7 | Control cabinet | Full set |

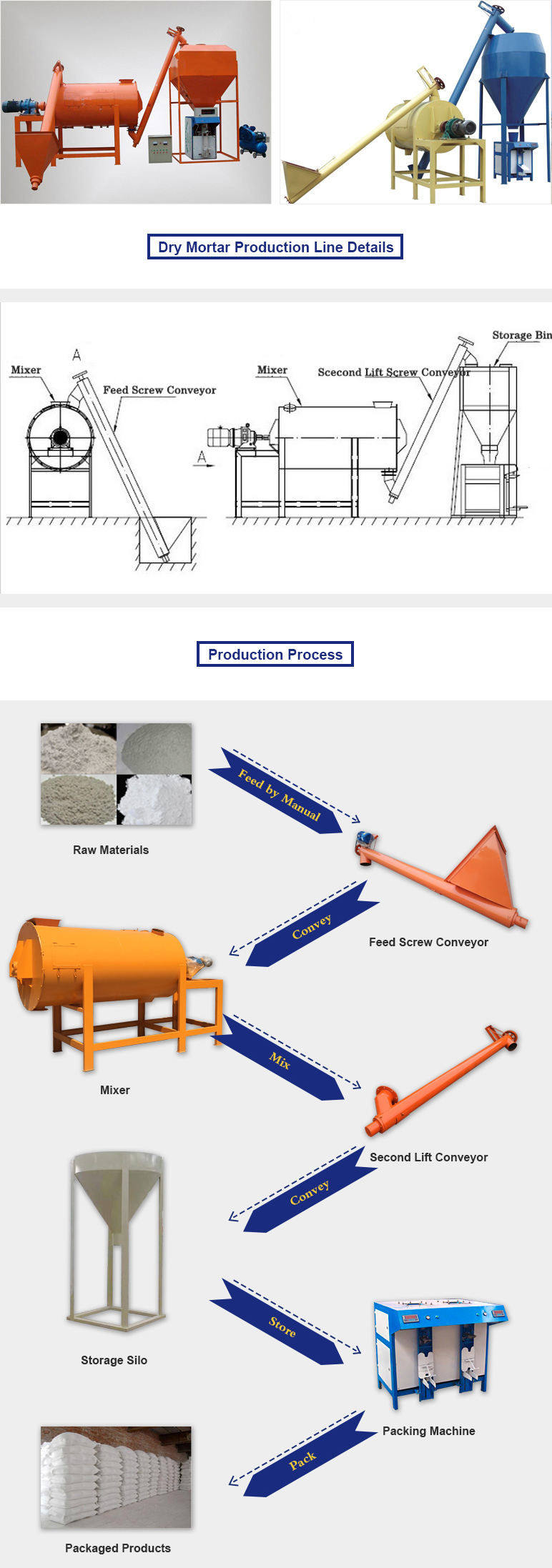

Screw Conveyor with Feeding Hopper and Spiral Ribbon Mixer:

The screw conveyor is of Φ165X3500mm, feeding material to the mixer. The outer and inner screw ribbon blade driven by high speed rotating shaft, mixing the material in maximum, inner screw ribbon blade forced the material to sides ,outer screw ribbon blade forced sides material to inward, mix the materials back and forth. In the same time, some material driven by screw ribbon do the radial motion, to form the convective mixing, so to achieve uniform mixing effect in relatively short time. The mixing time:10-15min/batch

Screw Conveyor:

The mixer mortar is transferred from mixer to finish product bin. The spiral body design with small diameter, high rotating speed and variable pitch ensures smooth, fast and uniform feeding of the product in the working process. The lubrication and sealing are reliable and leak-free. There is no waste of materials with good working environment.

Storage silo:

The storage silo is of 1.5m³, store the finished material and prepare for the packing machine, which improves the efficiency highly.

Packing Machine:

Valve type automatic dry mortar plant. 15-50kg/bag adjustable, the packing speed is 5-6s/bag. Fast packing speed, high weighing accuracy, high degree of automation, and simple operation.

Air Compressor:

balance the air pressure, provide air source for packing machine for quick packing and broken arch of finish product hopper.

Products pictures:

Projects show

Contact:

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatapp:+8613382200234