Valve bag packaging machine,valve bag packer DCS-VBSF

Product description:

Valve bag packaging machine DCS-VBSF is specially is suitable for powder and slice materials. The advantages are small dust and high precision. It is widely used for flour, titanium dioxide, alumina, kaolin, calcium carbonate, bentonite, dry mixed mortar and other materials.

Video:

Applicable materials:

Weighing range: 10-50kg

Packaging speed: 1-4 bags / min

Measurement accuracy: ± 0.1-0.4%

Applicable voltage: ac22ov-440v 50 / 60Hz three-phase four wire

Gas source:

Pressure: 0.4-0.8mpa, dry and cleaned compressed air,

Air consumption: 0.2m3/min

Working principle:

The material from the finished product warehouse into the buffer bin of the packaging machine, by the homogenization mixing system to homogenize the material, can effectively discharge the gas contained in the material from the buffer bin, at the same time, it also has the function of preventing material caking and bridging, so as to ensure the smooth packaging process. During the packaging process, the materials are filled into the packaging bag through the spiral controlled by frequency converter. When the filling weight reaches the preset targeted value, the packaging machine stops feeding, and the packaging bag is removed manually to complete a single bag packaging cycle.

Products pictures:

Details:

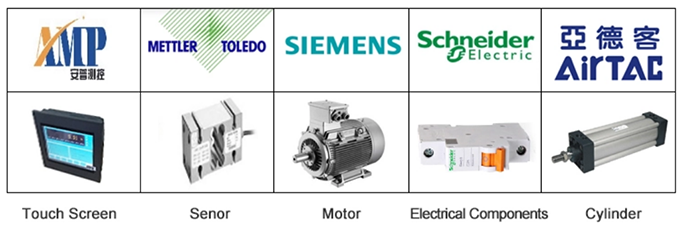

Our Configuration:

Contact:

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatapp:+8613382200234