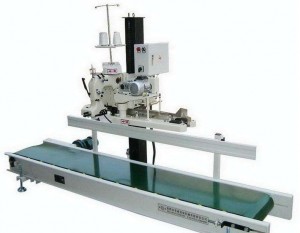

Automatic sealing machine coffee bag vacuum packaging machine PP PE plastic bags heat sealing machines

Introduction

Automatic continuous heat sealing machine can heat and seal thick PE or PP plastic bags with high quality, high efficiency and continuity, as well as paper plastic composite bags and aluminum plastic composite bags; it is widely used in chemical , pharmaceutical , grain, feed and food industries.

Technical parameter

|

Model |

DCS-32 |

|

Supply voltage(V/Hz) |

Three phase(3PH)AC 380/50 |

|

Total power (KW) |

4 |

|

Transmission power (KW) |

0.75 |

|

Electric heating power (KW) |

0.5×6 |

|

Sealing speed (M / min) |

0-12 |

|

Plastic bag material (mm) |

Polyethylene (PE) ,polypropylene (PP) film |

|

Total thickness of plastic bag (mm) |

≤1.0 |

|

Sealing width (mm) |

10 |

|

Distance from sealing center to ground (m) |

750-1450 |

|

Temperature control range (℃) |

0-300 |

|

Air supply pressure (Mpa) |

0.6 |

|

Cooling mode |

wind cooling |

|

Overall dimension (L) × W × H)(mm) |

2830×950×1800 |

|

Net weight (kg) |

320 |

Machine pictures

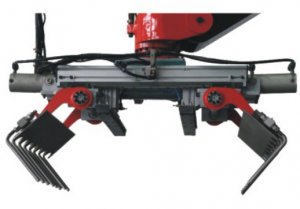

Other auxiliary equipment

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatsapp:+8613382200234