Sand bag filler, Sand Bagging Machine, stone bagging machine, sand bagger, gravel bagging machine

Sand bag filler, Sand Bagging Machine, stone bagging machine, sand bagger, gravel bagging machine

A sandbag filling machine is a mechanical device that is used to fill sandbags quickly and efficiently. Sandbags are commonly used to protect homes and buildings from flooding, to create barriers for erosion control, and for other construction and landscaping purposes.

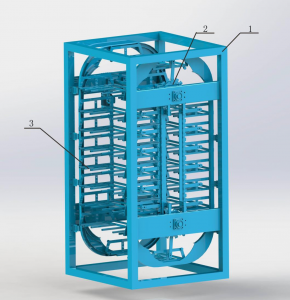

The sandbag filling machine works by using a Wing Wall 2 Cubic Yard hopper that is filled with sand. There are two vibration agitators for materials bridging together. The sand is then dispensed through a funnel with powered conveyor belt feeder into the sandbag. The machine is typically operated by one or two people who hold the sandbag open while the sand is being dispensed. The machine can fill sandbags at a rate of 800-1200 per hour, which is much faster than filling sandbags manually. Adjustable Fill Weight For 1 to 5,000 lb Bags.

Fills Small Bags, Bulk Bags, Pots, & More.

There are different types of sandbag filling machines available, including manual and automatic models. Manual machines require the operator to turn a crank or handle to dispense the sand, while automatic machines are powered by electricity or gas and can fill sandbags automatically.

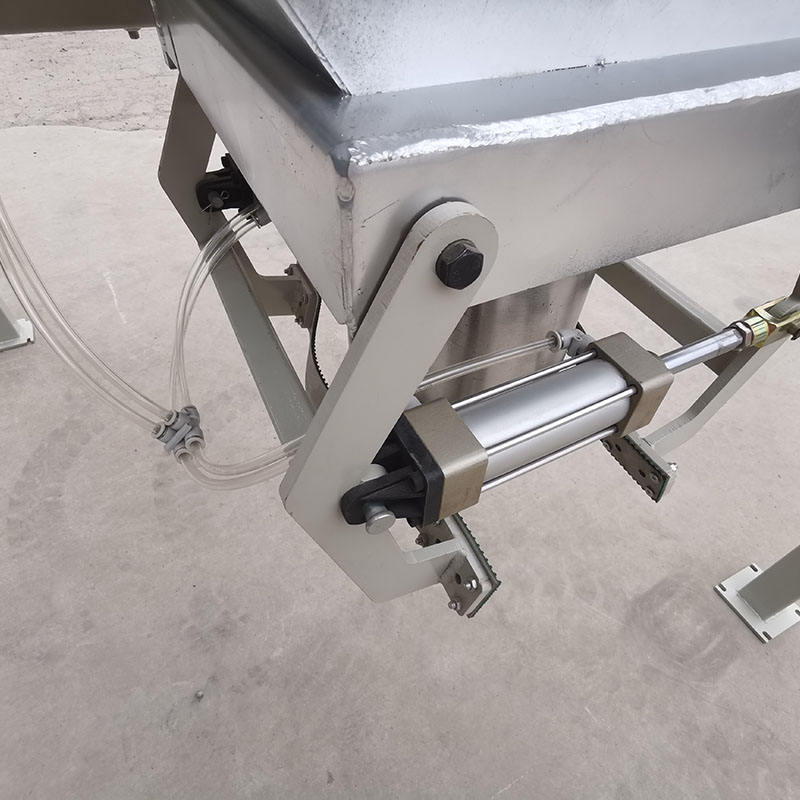

The worker load the bag to the pneumatic bag clamp then it will fill automatic.

After that the bag can be sealed manually or by sewing machine.

Power Source:

EXTERNAL – Stock machines require external power (120V @ 10A).

SELF POWERED – On board 7500W generator for just-add-fuel bagging. Can still utilize commercial power when available.

There are fixed stand sewing machine and portable sewing machine.

Operation

The Sand bag filler will make bag filling quick, safe, and simple. The idea is to let an automated electric motor do the shoveling for you while working in tandem with a sewing head to rapidly seal many bags. This speeds up the process considerably, creates dependable production levels, and reduces workload.

1. Setup the Sand bag filler on a flat/level surface. Ensure the machine feet cannot sink into soft ground. Be sure the hopper is properly aligned over the bagging belt. Provide 120V power and 120 PSI air supply.

2. Deploy outrigger feet. Inside of each leg base is an orange rectangular tube outrigger post that should be pulled out and bolted into place. This will create a 7’ x 7’ footprint and help prevent hopper tipping.

3. Fill hopper with sand, gravel, or any other loose flowing material you wish to bag. Do not overfill hopper. If material cascades over side, front, or rear of hopper, then the hopper is overfilled.

Note: If bagging extremely low density, fluffy material (such as mulch), you may need to remove the flow control inside of the hopper.

Unplug machine, then remove eight bolts at the bottom of the flow control unit inside of hopper (bolted to posts on front and rear hopper walls). This should only be done if you have confirmed that your material cannot flow through the hopper with unit in place.

4. Set your bag weight by adjusting the fill level up or down. First time users will require some trial and error (fill and weigh each bag) until the desired setting is found. We suggest keeping a chart handy for common settings.

Gate Adjustment: For fastest bagging (most material per second), you will want to raise the hopper output gate. For highest weight accuracy between bag cycles, you will want to lower this gate.

5. Set your agitation level. For wet sand and materials that are difficult to flow, we suggest running both vibrators (V12) at 40% run time (in Settings Mode).

6. Set your bags per pallet/container (in Settings Mode).

7. Set up your sewing head with the thread behind the sewing table, fed up through the thread guide arm, and into the sewing machine as shown in the diagram above.

Sewing machine should be plugged into the foot petal, with power plugged into the other side of foot petal plug.

8. Setup your palletizing/bulk bagging stations.

9. Set empty bags in a stack near spout position.

If bags have tie strings, we suggest cutting them off while the bags are stacked together.

10. Begin filling sandbags. Lift each bag to the spout, engaging the activation touch switch in the process. Once bag clamps activate, the operator should open and prepare the next bag.

Never transport machine with material inside of hopper.

11. After a bag releases from the clamps the lower conveyor will carry it to the sewing position. Sewer should guide the bag into the jaws of the sewing machine. Once the bag is touching the jaws, the operator should press the foot petal, turning the sewing machine on.

Sewing sandbags closed is cheaper than zip ties, faster than hand tying, and stronger than any other method. Sandbags filled and sewn closed are rectangular, and substantially easier to stack than bags with one flat side and one bunched up (tied or ring closed) side.

Always allow the sewing machine to pull the bag though the feed dogs on its own. The lower conveyor belt’s speed exactly matches these feed dogs. There should never be added pressure (push or pull). The sewing operator is only guiding the fabric into the feed dogs, not pulling it through!

This prevents needle deflection which leads to machine timing issues.

Once through the sewing head, the operator should release the foot petal and push the trailing thread chain into the thread cutter at the rear of the sewing machine. Replace the sewing needle every 40 hours of use.

12. The finished bag will then be carried to the pallet stacker. This position should be rotated out as they generally do all of the “heavy lifting.” At full speed, the sand bag filler bags 24 metric tons of sand per hour. Rotating positions is necessary to achieve full production speed with only four operators.

13. When finished with production, it is a good idea to empty the hopper. Wet material such as sand stored inside of the hopper will accelerate rust and corrosion and shorten the machine life. Unplug the sewing table and lower each leg to lowest setting. Stow the sewing table by sliding table into the guided track beneath the hopper. You can now drive your loader bucket underneath the filling spout, and using Manual Jog Mode, quickly empty the hopper. Lastly unlock the two locks on the filling belt and retract fully.

14. For long term storage or transport, it is best to re-install the plywood paneling using the pre-drilled plywood sheets that originally shipped with the equipment.

BAGS MORE THAN JUST SAND. The sand bag filler is also used to bag mulch, lava rock, salt, aggregates, and other dry goods. This system sets up a fully functional bagging plant for incredibly low cost. Convert your FIBC bulk bagged goods into smaller (more profitable) bags.

Overall, a sandbag filling machine is an essential tool for anyone who needs to fill sandbags quickly and efficiently. It can save time and labor, and can help to protect homes and buildings from flooding or erosion.

Sandbag filling machines are designed to fill sandbags quickly and efficiently, making them ideal for flood protection, erosion control, construction, and landscaping. The machines work by using a Wing Wall 2 Cubic Yard hopper that is filled with sand, which is then dispensed through a funnel with a powered conveyor belt feeder into the sandbag. The machine can fill sandbags at a rate of 800-1200 per hour, which is much faster than manual filling. Sandbag filling machines are available in both manual and automatic models, with the latter being powered by electricity or gas.

To operate the machine, users must set it up on a flat, level surface and deploy the outrigger feet to prevent hopper tipping. They can then fill the hopper with sand or other materials and adjust the fill level and agitation level as needed. The bags per pallet/container can also be set in the machine’s settings mode. Users should set up their sewing head with the thread behind the sewing table, fed up through the thread guide arm, and into the sewing machine.

Once the machine is set up, users can begin filling sandbags by lifting each bag to the spout and engaging the activation touch switch. Once the bag clamps activate, the operator should open and prepare the next bag. After a bag releases from the clamps, the lower conveyor will carry it to the sewing position, where the operator should guide the bag into the jaws of the sewing machine. The finished bag will then be carried to the pallet stacker, which should be rotated out to achieve full production speed with only four operators.

Mr. Yark

Whatsapp: +8618020515386

Mr. Alex

Whatsapp:+8613382200234