Inkqubo yokuhambisa isilayidi yomoya yaseTshayina yesamente

Inkqubo yokuhambisa isilayidi yomoya yaseTshayina yesamente

Yintoni isilayidi somoya?

Isilayidi somoya, ekwaziwa ngokuba sisilayidi somoya, isilayidi somoya esihambisa umoya, isilayidi somoya wesilayidi somoya, inkqubo yokuhambisa isilayidi somoya.

Isilayidi somoya luhlobo lwezixhobo zokuhambisa umoya ezisetyenziselwa ukuhambisa izinto zomgubo owomileyo, kwaye kuthatha ifeni njengomthombo wamandla, okwenza izinto ezikwi-chute evaliweyo zihambe ngokucothayo kwisiphelo esithambekele phantsi kwemeko ye-fluidization, eyona nxalenye iphambili yesixhobo ayinayo indawo yokuhambisa, ukugcinwa lula, ukutywinwa kakuhle, akukho ngxolo, ukusetyenziswa okukhuselekileyo, ukuhanjiswa okufanelekileyo, ukuhambisa amandla kunye nokutshintsha amandla amancinci kunye nokutshintsha amandla. Ukothulwa kwezinto ezinamanqaku amaninzi.

Isilayidi somoya sisetyenziswa kakhulu kwishishini lezinto zokwakha, kwimizi-mveliso yeekhemikhali.

Iimpawu zobuGcisa:

1.Isakhiwo esilula, kulula ukuyifaka kunye nokugcina, iindleko eziphantsi zemveliso, kunye neendleko eziphezulu

2.Hambisa uninzi lomgubo owomileyo njengesamente,udaka olomileyo,uthuthu lwempukane, umgubo, istatshi, njl.

3.Ilungele ukutshintsha indlela yothumelo

4.Ukulungeleka kwi-multi-point feeding material kunye nokukhutshwa kwezinto ezininzi.

5.Evalelweyo, ayinathuli

6.Akukho monakalo kwimveliso ephathwayo (ukunciphisa inkunkuma)

7.Akukho malungu ashukumayo (ukunciphisa ukuguga, iindawo ezisecaleni kunye nokwandisa ubomi benkonzo)

8.Ukusetyenziswa kwamandla aphantsi

9.Ingxolo ephantsi,ifeni okanye isivuthelo sikude kwiconveyor.

Iimpawu kunye nobungakanani bokusetyenziswa

Isilayidi somoya sisixhobo sokuhambisa esithe tyaba esifakwe kwi-engile. Izinto ezigqithisiweyo zihamba ukusuka phezulu ukuya ekupheleni okuphantsi kwimeko yolwelo. Ifanelekile kwizinto ezinomgubo ekulula ukuzikhupha, ezifana nesamente kunye ne-fly ash, kodwa azikwazi ukuthutha izinto ezinobungakanani besuntswana elikhulu, umthamo omkhulu wokufuma, kunye nokuxinana okuphezulu okungekho lula ukukhupha.

Usetyenziso lwezilayidi zomoya

Iiparamitha zobugcisa

| Umzekelo | Ukuhambisa umthamo (itoni/yure) | Ubukhulu bokusetyenziswa kwamandla (KW/10M) | Umthamo womoya (m3/min/10m) |

| DCS-200 | 45-70 | 0.6-1.6 | 3.0-8.0 |

| DCS-250 | 70-110 | 0.8-2.0 | 4.0-10.0 |

| DCS-300 | 105-160 | 0.9-2.5 | 4.5-12.50 |

| DCS-400 | 160-260 | 1.2-3.2 | 6.0-16.0 |

| DCS-500 | 260-400 | 1.5-4.0 | 7.5-20.0 |

| DCS-600 | 400-680 | 1.9-5.0 | 9.5-25.0 |

| DCS-800 | 680-1150 | 2.4-6.4 | 12.0-32.0 |

Ezi parameters zingentla zezereferensi kuphela, kwaye ixhomekeke kuqinisekiso lwethu lokugqibela.

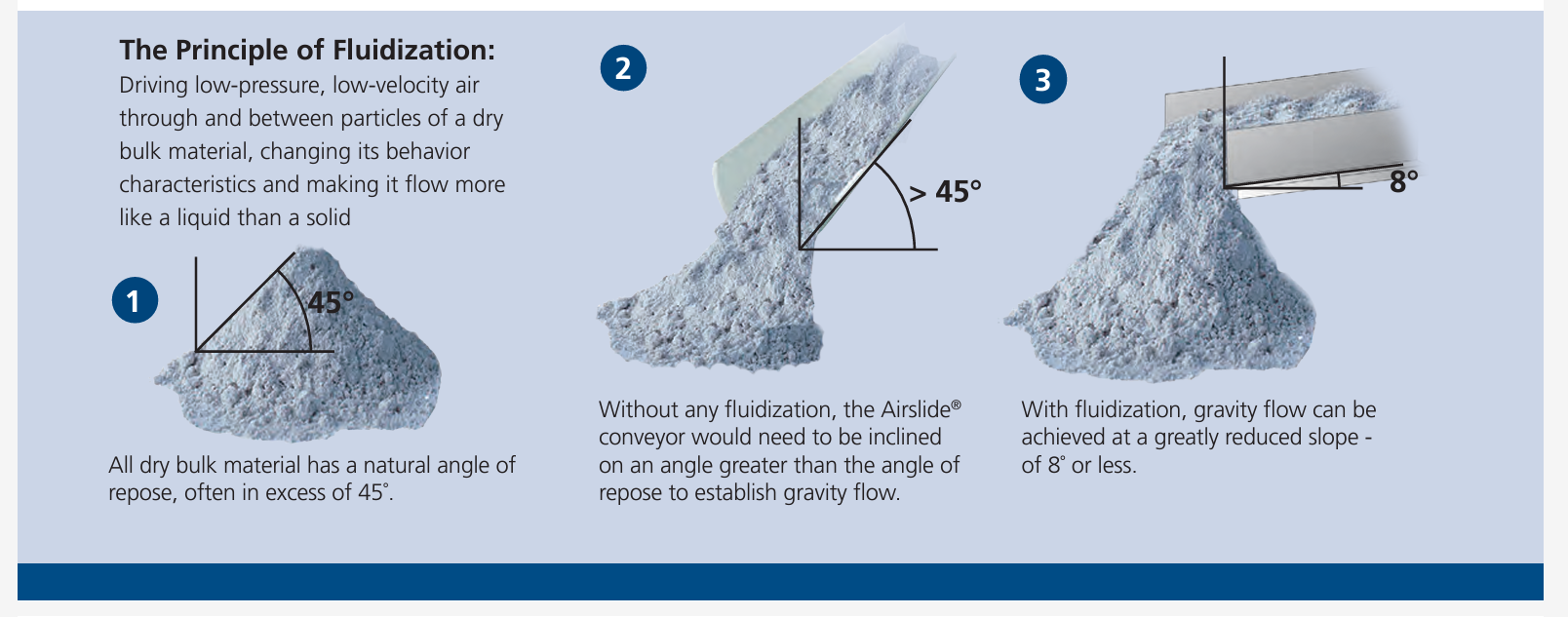

Umgaqo wokusebenza:

Umoya woxinzelelo oluphezulu oluphonswe yi-blower lungena kwindawo ephantsi yesilayidi somoya ukusuka kwi-air inlet ngokusebenzisa i-air duct, umoya usasazeka kwindawo ephezulu ngokusebenzisa i-air-permeable layer, kunye nezinto eziphathekayo zomgubo ezithunyelwayo zingena kwindawo ephezulu, emva kokuba i-inlet feed ingena kwindawo ephezulu, ngaphezu kwe-permeable layer yi-gas flow flow kunye ne-particle ye-valve yesiqhelo kunye ne-gas velocity ethile. iimeko, icandelo lomaleko wezinto zohlulwe ngokwemigangatho emine ukusuka ezantsi ukuya phezulu: umaleko osisigxina, umaleko we-gasification, umaleko ohambayo kunye ne-static layer. Ngenxa yokulungelelaniswa kwe-chute, umgubo owenziwe ngumgubo uphuma ukusuka phezulu ukuya ezantsi phantsi kweempembelelo ezimbini zomxhuzulane kunye nokuhamba komoya, kwaye ekugqibeleni ukhutshiwe kwindawo yokuphuma.

Iiparamitha zobugcisa

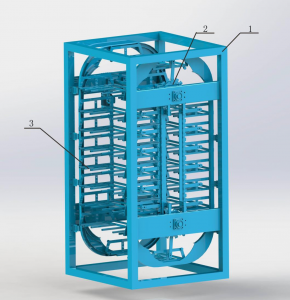

Ulwakhiwo

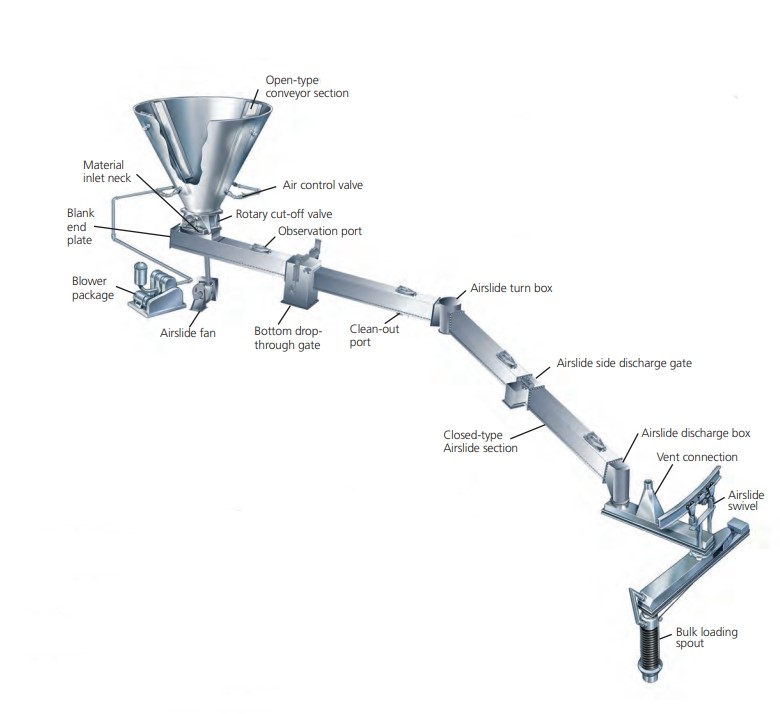

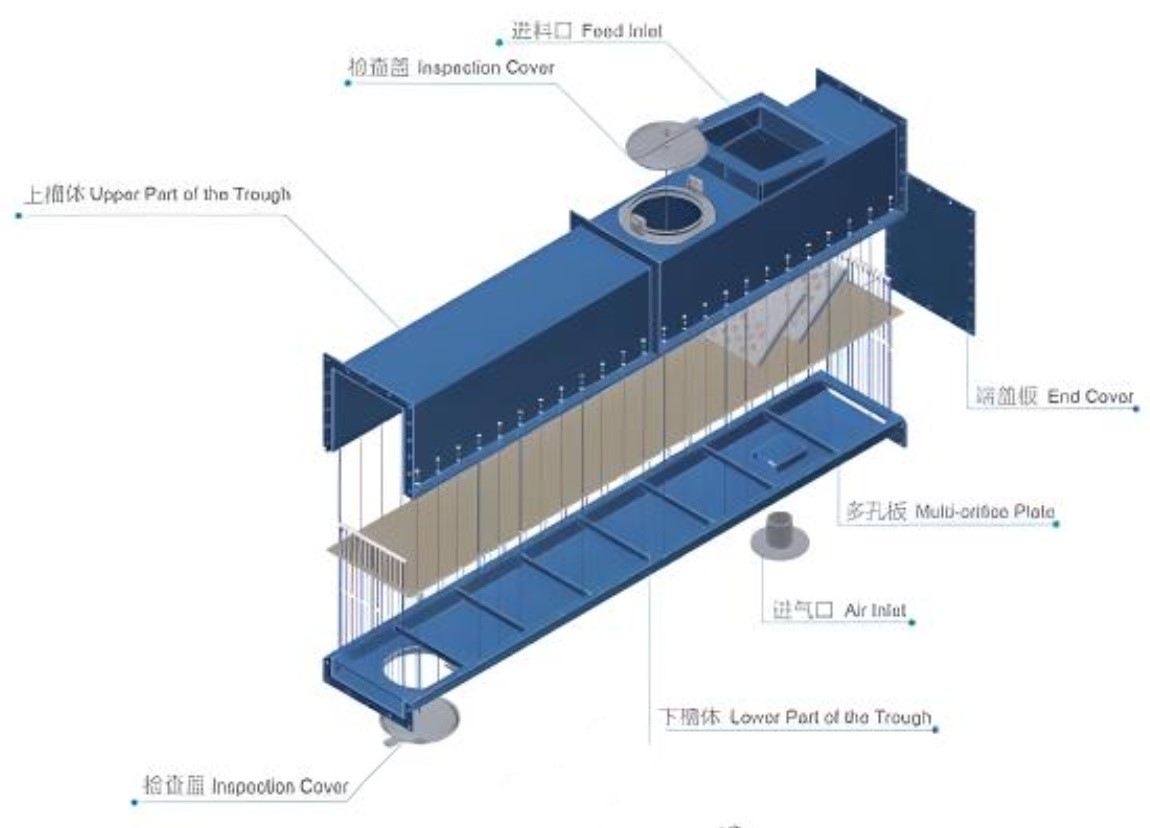

1. Imizimba ye-chute ephezulu nasezantsi: Umzimba we-chute ngokuqhelekileyo wenziwa ngeepleyiti zentsimbi ezicinezelwe kumacandelo axande, kunye nobude obuqhelekileyo be-2m okanye i-3m yecandelo ngalinye, kunye neeflange ezenziwe ngentsimbi ecaba kuzo zombini iziphelo.

2. Umaleko ophefumlayo: Zimbini iindidi zomaleko ophefumlayo: umaleko omtsha ophefumlayo wepolyester kunye nebhodi enemingxuma ephefumlayo.

3. I-air inlet: I-air inlet yenziwe nge-cylindrical air duct edibeneyo kwi-plate ephantsi ye-chute engezantsi.

4. Ichweba lokutya: I-port yokutya ibekwe kwindawo ephezulu ye-chute ephezulu, enokuthi ibe uxande okanye isetyhula. Ukunciphisa amandla empembelelo yezinto kunye nokuthintela ilaphu le-polyester ukuba lingaboli okanye lonakaliswe, ipleyiti yensimbi ene-porous plate kufuneka ifakwe kwindawo ephezulu yomaleko ophefumlayo kwizibuko lokutyisa.

5. I-port yokukhupha: I-port yokukhupha ihlulwe ekupheleni kunye ne-middle discharge port. Indawo yokukhupha ephakathi ibekwe kwicala le-chute ephezulu kwaye ixhotyiswe ngepleyiti yeplagi yokuthintela imathiriyeli.

6. Ivalve yokuvala igesi: ilawula ubungakanani bomoya osetyenziswa kwi-chute.

7. Izibuko lokujonga: ibekwe kwicala le-chute ephezulu, esetyenziselwa ukujonga ukuhamba kwezinto ngaphakathi kwe-chute.

Ukhetho Lwenkqubo:

Jika iibhokisi:Isetyenziselwa ukuphambukisa ukuhamba kwemveliso.

Ukukhutshelwa emacaleni:Vumela imathiriyeli ukuba ijikelwe kwezinye iinkqubo phakathi kwesiqalo nesiphelo sesihambisi somoya womxhuzulane.

IiSango zesilayidi okanye iiValuvu zeGubu: Isetyenziselwa ukuvala kunye nokulawula ukuhamba kwempahla kwigumbi eliphezulu.

Ukuqokelelwa kothuli:Ifakwe ekupheleni komhambisi ukuqokelela uthuli olubalekayo.

Umgqomo okanye isihluzo:Ukuze kuhanjiswe izinto ngokusebenzisa isilayidi somoya, umoya ungeniswa kwaye uqulethwe ngaphakathi kwenkqubo. Ngexesha elithile, lo moya kufuneka ungene ngokufanelekileyo ngomgqomo okanye isihluzo ngaphakathi kwenkqubo.

Umhlalutyi weenkqubo unokucebisa ukuba kukho naziphi na kwezi zikhetho ekufuneka ziqwalaselwe inkqubo ethile yokuhambisa umxhuzulane womoya.

Iiprojekthi zemifanekiso yereferensi

UMnu. Yark

Whatsapp: +8618020515386

UMnu. Alex

Whatsapp: +8613382200234